Robotic TIG welding improves welding consistency, quality, and productivity. However, TIG (GTAW) requires more skills than other welding processes and has numerous challenges, even with robots in the picture.

The TIG welding process can produce high-quality welds on almost any material if everything is done right. Below, you’ll learn about robotic TIG welding problems, solutions, and alternatives.

In this article:

• The Challenges Of Automating TIG Welding With a Robot ›

• 1. TIG Welding Is Too Slow ›

• 2. Tungsten Erosion ›

• 3. TIG’s High-Frequency Can Interfere With Sensitive Equipment ›

• 4. Robotic TIG Head Can Be Bulky ›

• 5. The Robot Must Have Sensors For Tip-To-Work Distance ›

• Robotic Tig Welding Alternatives ›

• Cobot Vs. Robot Welding – Which Is More Appropriate For You? ›

• Why Laser Welding Cobots Are The Best Alternative To TIG Automation ›

The Challenges Of Automating TIG Welding With a Robot

Automating TIG has several challenges you need to address. First, you’ll need a skilled TIG welder to program the robot. Depending on the robot system, you might also need a programmer who understands TIG’s characteristics. Unfortunately, challenges with automating TIG don’t stop there. Below are some of the most troublesome issues that can arise when automating TIG.

1. TIG Welding Is Too Slow

Even if automated with a robot, TIG is usually slower than robotic MIG and laser welding. Manual TIG is extremely slow. Automating the process improves efficiency, but the low welding speed remains the biggest bottleneck of manual or robotic TIG welding.

With the right TIG equipment and robot, you could get more speed for some applications. For example, using hot-wire TIG boosts speed and weld deposition. However, hot wire has its issues, like complex equipment, arc deflection, and the possibility of the wire causing a second arc.

Generally, you won’t find an ideal solution to the TIG’s low productivity. The best option is to look at alternatives like robotic laser welding, which is faster and offers better weld quality.

2. Tungsten Erosion

The tungsten electrode erodes with use. Some applications erode it faster, like using high amps and welding with a filler wire. As the electrode erodes, the arc characteristics will change. So, you’ll have to monitor the welding process and change the , which can become a challenge with a robotic TIG welding system.

You could invest in robots that can change the tungsten automatically. They can detect an eroded tungsten tip and replace the electrode with a fresh one. However, this increases the costs of the robotic TIG system.

3. TIG’s High-Frequency Can Interfere With Sensitive Equipment

High-frequency TIG arc start is the cleanest way to start welding. No tungsten contact with the workpiece means no tungsten inclusions in the weld.

However, HF can interfere with sensitive electronics, like computers, laptops, CNC machines, and even the robot controller. HF can even blow out the robot controller.

There are two ways to minimize the HF effect: grounding the robot cell to the building ground and using case-hardened robots. Grounding will help but only a little. Shielding the robot arm, cables, and controller is the only real way to prevent HF from affecting the system. However, again, this raises the system costs, reducing the cost-effectiveness of robotic TIG.

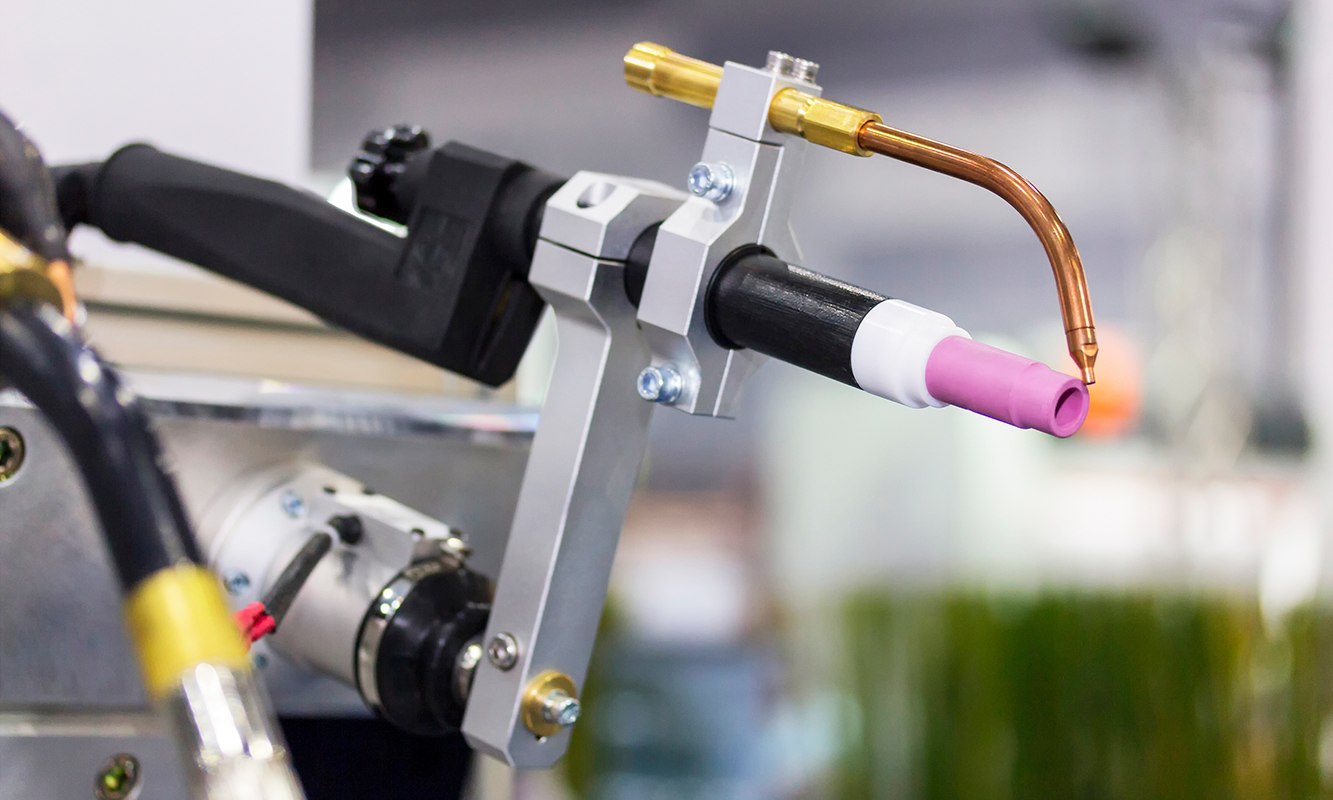

4. Robotic TIG Head Can Be Bulky

Depending on the system and if you need to use a filler wire, the robotic TIG head can be bulky. So, you might have a hard time approaching the joint with a robot.

With manual TIG, you’ve probably gotten used to the process flexibility. Manually, you can almost always approach the joint with a TIG torch, especially with a flex head. But, you should carefully evaluate any TIG robot’s head setup to see if it can approach the parts you typically weld.

5. The Robot Must Have Sensors For Tip-To-Work Distance

Maintaining the tip-to-work distance is critical with TIG. This distance is proportional to the arc voltage, so changing it affects the width-to-depth ratio. Manual TIG welders can compensate for joint variations by controlling the arc length. But to achieve the same with a robot, it must be equipped with sensors or cameras to adapt to joint changes.

Robotic TIG Welding Alternatives

While TIG is suitable for precision and weld quality, it’s still a challenging process to automate. Besides automation struggles, TIG is much slower than MIG or laser welding. MIG can’t always produce TIG-like results, while laser almost always beats TIG where applicable.

TIG welding is often a bottleneck in any production business. TIG only makes sense if your parts can’t be welded with any other process, which is usually not the case. Even if you have phenomenal welders on your team and excellent robots, your production speed is suffering with TIG if alternative welding processes are suitable for your application.

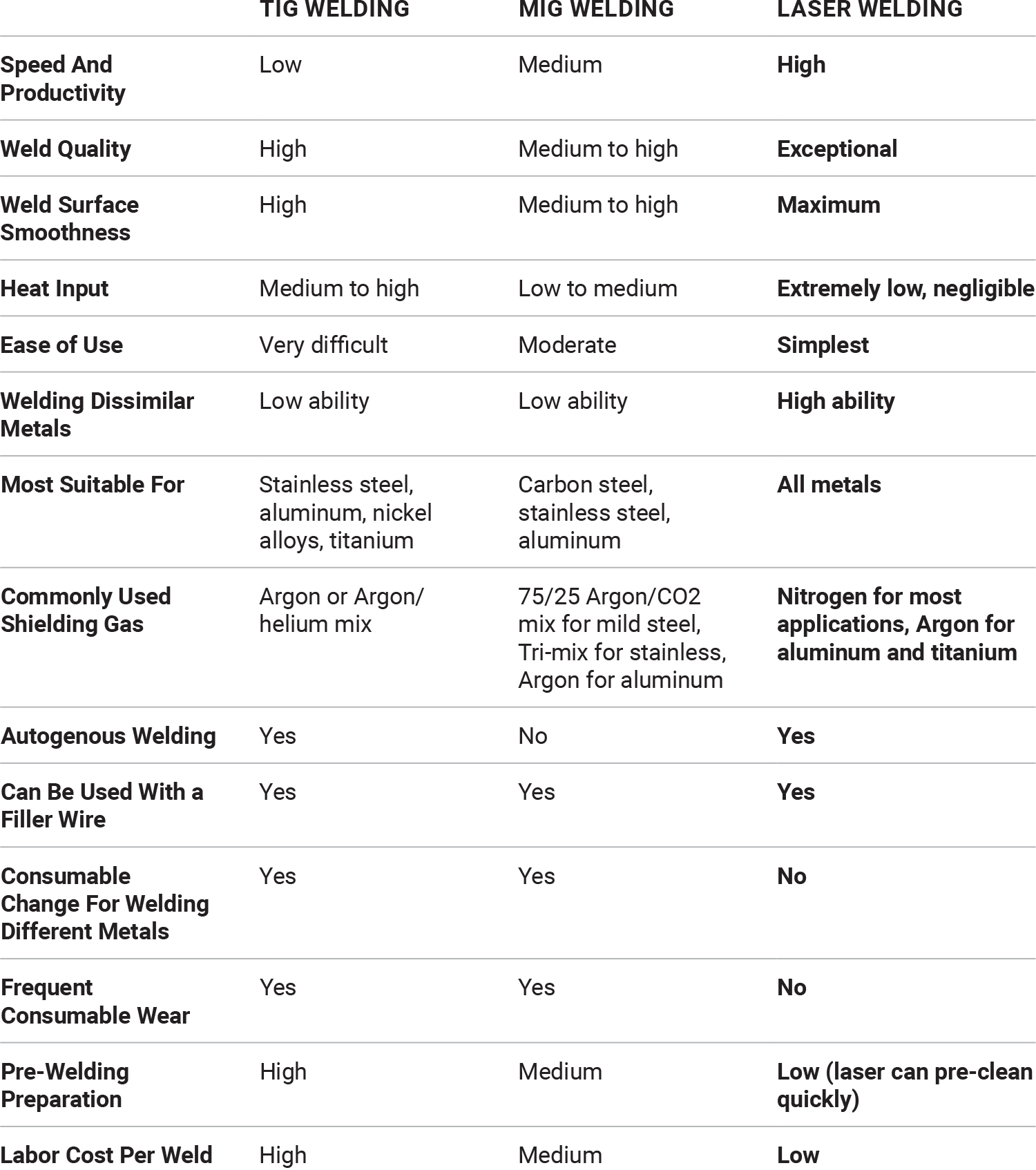

TIG Welding Vs. Laser Welding

For almost all applications up to 1/4-inch thick, laser welding is better than TIG across the board. Although laser welding equipment can be more costly than TIG, the price difference pays off quickly, thanks to the laser’s fast ROI.

In particular, fiber laser welding is about 4X faster and almost eliminates the excessive heat input. It uses far simpler equipment than TIG and requires minimal training.

You can also achieve excellent weld quality on dissimilar metals with laser, while this is much more challenging with any arc welding, including TIG.

Laser welding equipment requires different safety measures than TIG, like having a Laser Safety Officer (LSO), certain engineering controls, and a safe laser enclosure.

And most importantly, laser welding is much easier to automate than TIG. You don’t need specialized staff with years of welding experience. For example, our Laser Welding Cobot System is so easy to use that even non-welders can make their first welds on the first day.

We have a complete guide covering laser welding vs TIG welding in great detail. Since laser welding is the best alternative to TIG, we highly encourage you to read it.

TIG Welding Vs. MIG Welding

MIG welding is faster than TIG, giving you a significant productivity boost. However, TIG has a much better weld appearance and smoothness, making it more suitable for food and beverage and similar applications.

MIG can’t be used without a filler metal. The wire acts as an electrode, making it integral to the process. So, no autogenous welding. High-precision welding is also out of the picture, as the MIG’s arc is much more erratic and transfers the filler metal, unlike TIG, where the filler is added separately.

You can learn more in our full MIG vs TIG welding comparison.

TIG Vs. MIG Vs. Laser Welding Comparison Table

Discover more about laser welding in our free ebook. You’ll learn about laser safety equipment, automating the welding process, and the costs of the system.

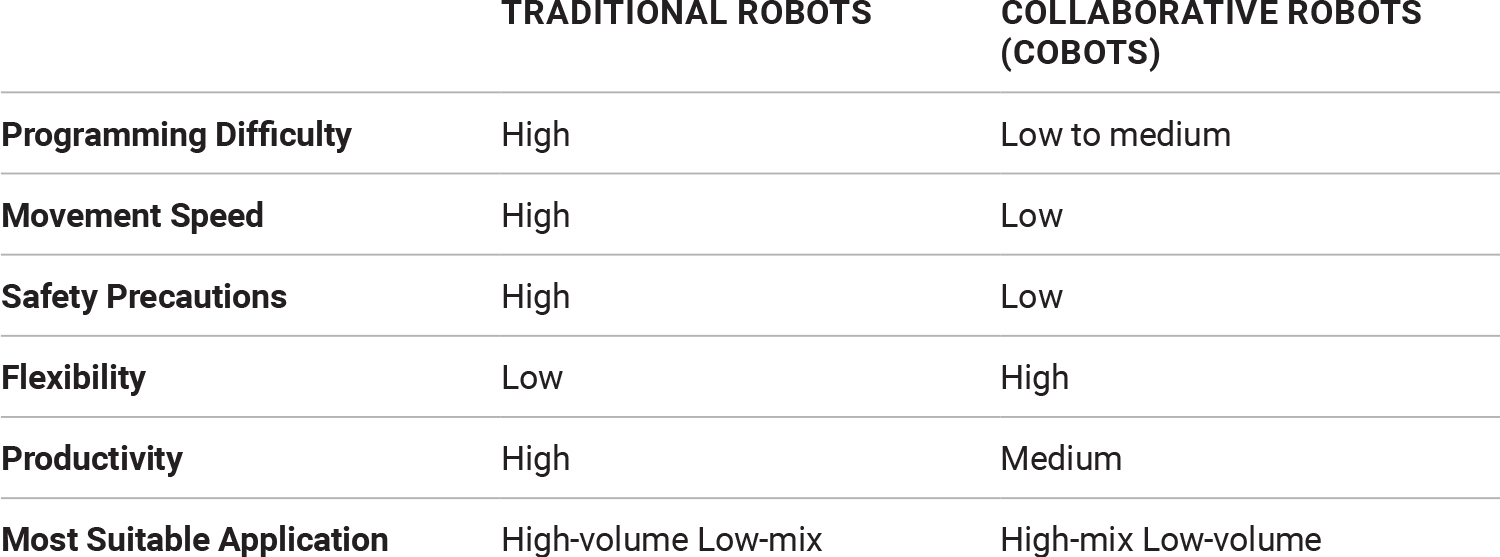

Cobot Vs. Robot Welding – Which Is More Appropriate For You?

Regardless of which welding process you wish to automate, you are looking at two different robot types.

Cobots work alongside your welders. They are far safer than robots, as they can’t hurt the operator if they make contact. The biggest advantage for small to medium manufacturers is cobot’s flexibility. They are easier to program and can be quickly reprogrammed for another part batch.

Traditional robots are faster and more dangerous. They require a specialized safety approach. But, they provide drastic productivity gains when making massive part batches, like 10.000+ pieces.

Why Laser Welding Cobots Are The Best Alternative To TIG Automation

Even if you use a TIG cobot, you’ll still face the challenges we discussed so far. Cobots are easier to handle than traditional robots. But, TIG’s difficulty and low speed remain the bottlenecks of the process. Cobots won’t make a meaningful difference in making TIG competitive with laser welding.

Manual and automated laser welding is far easier than TIG. A non-welder can make high-quality laser welds with less than a day of training. So, automating the process with a cobot is drastically easier than robot/cobot TIG.

Cobot laser welding is the most productive, cost-efficient process for near-perfect welds. If you weld sheet metal and thicknesses up to 1/4-inch thick, cobot laser welding is perfect for you.

Our Laser Welding Cobot System requires no code programming. All your welders need to do is manually guide the cobot’s laser torch to the joint and minimally interact with a teach pendant. You can make laser welds in less than 90 seconds!

Get your free laser welding ebook to learn more, and contact our team to discuss how our laser cobot can boost your productivity and bottom line.