Eliminate Idle Spin Times

and Maximize Profits

Take Advantage of CNC Machine Tending Cobots

—Without the Implementation Hassles

Straightforward

Implementation

Easy set up and implementation keeps production moving with no downtime.

Very Easy

to Use

No experience with collaborative robots required! Upskill your machinists to use the cobot and assign them to more value-added tasks!

Unmatched

flexibility

Connect your CNC machine cobot to any new or existing machine tool without the headache of programming or hard wiring.

Failing to adopt automated CNC machine tending will continue to result in decreased productivity and profits.

Labor shortage

Are you struggling to find a CNC operator or machinist? Are machinists spending too much time on monotonous, repetitive tasks rather than work that demands their skills?

Reduced productivity

Are time-consuming, cumbersome jobs forcing you to extend deadlines due to limited staff? Are fatigue, shift changes, and breaks compromising production performance?

Complexity of other CNC tending robots

Have you explored CNC robots but can’t find a truly turnkey solution? Are you always wondering how to connect your CNC with the robot?

Discover the CNC Machine Tending Cobot Systems and put an end to the challenges caused by implementing traditional CNC loading robots.

Increase Your CNC Machining Output

Without Hiring More Machinists.

Raise Production Capacity and Efficiency With a CNC Machine Tending Cobot

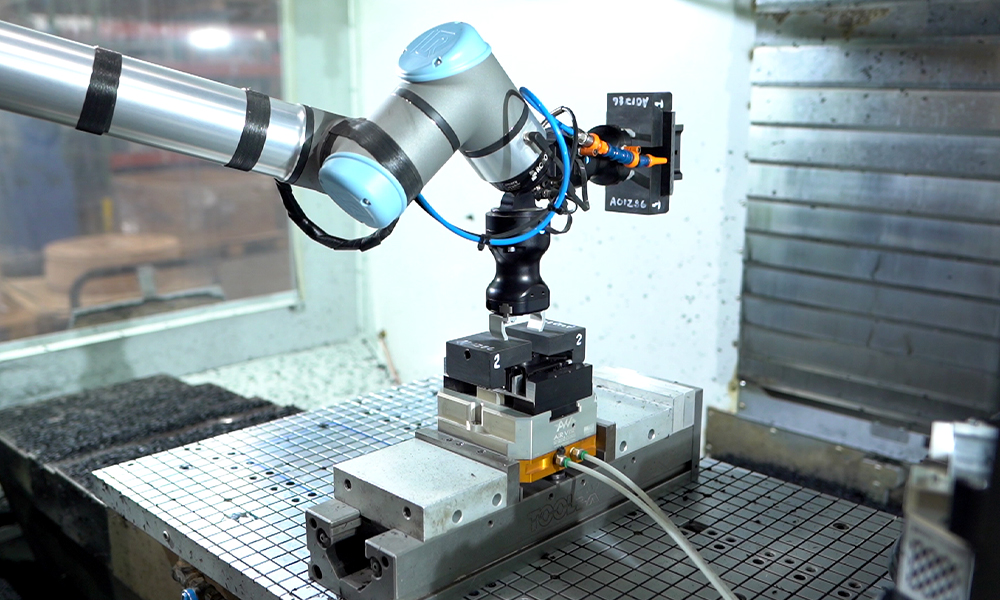

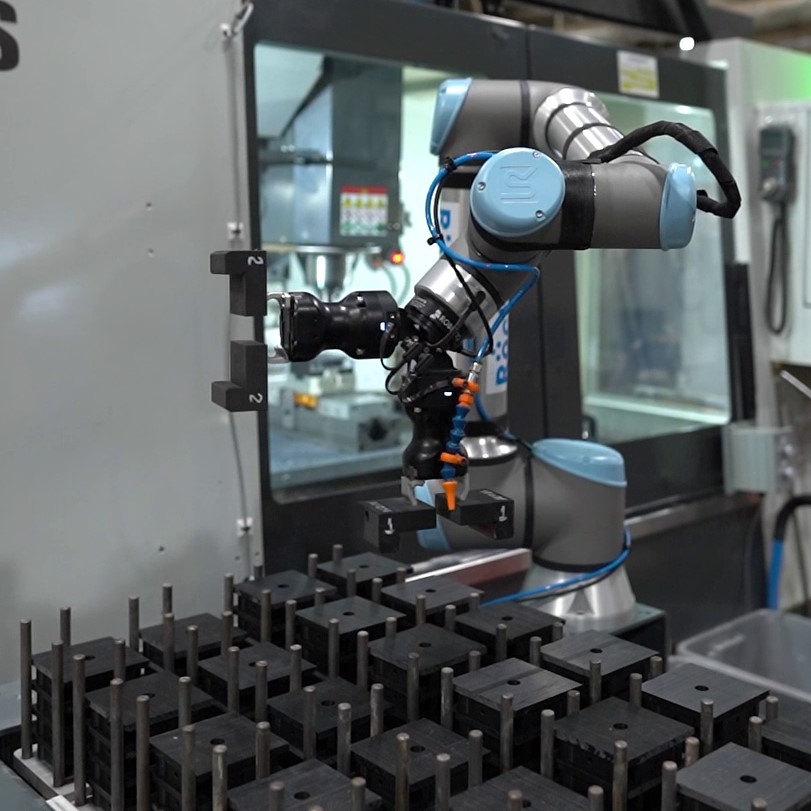

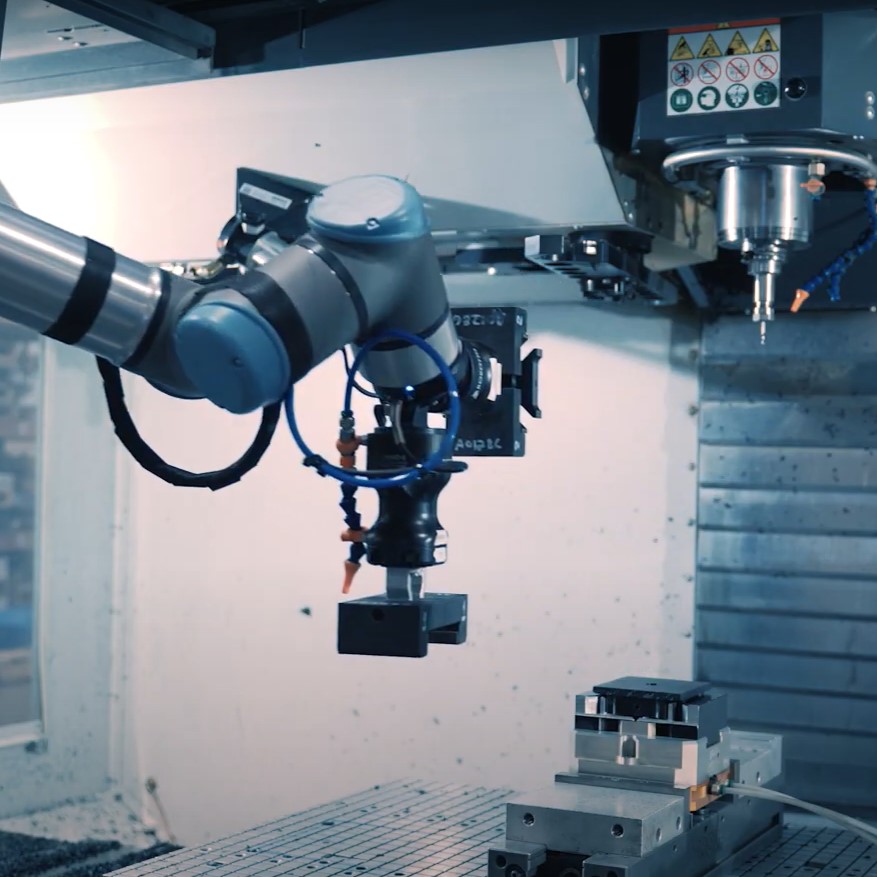

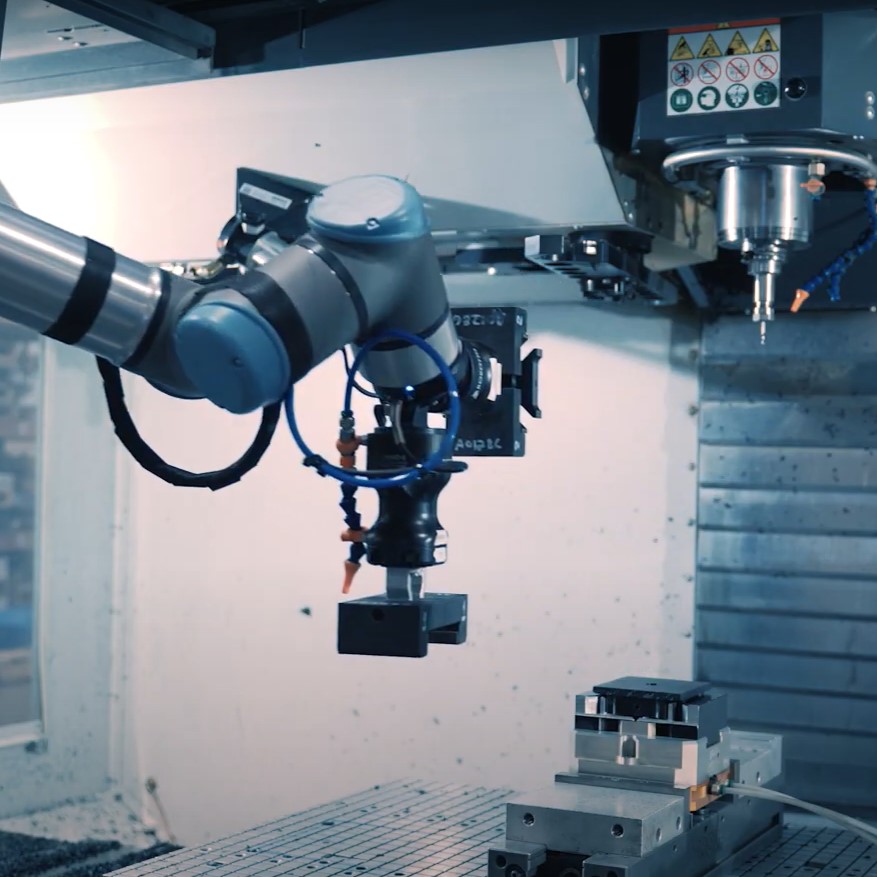

Legacy CNC machine tending robots are complicated to set up and operate due to advanced technical programming and difficult hard wiring. Cobot Systems’ CNC machine tending cobots are synonymous with simplicity. Maximize your team’s productivity and optimize their time by enabling your machinists to simultaneously operate multiple cobots.

Benefit from a Turnkey CNC Machine Tending System

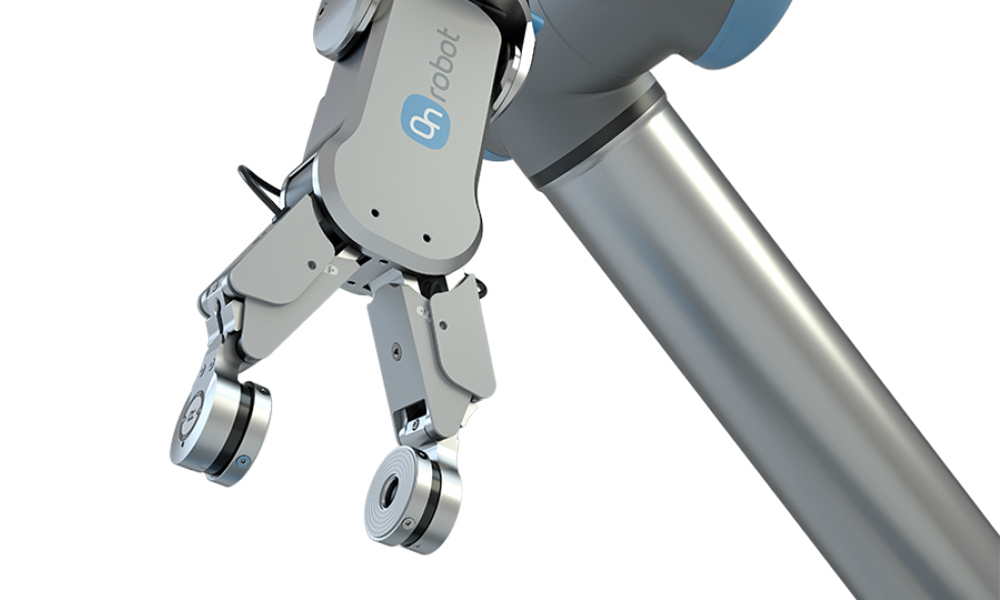

Cobot Systems’ CNC machine tending cobots feature all the functionalities you need to automate your workflows quickly and safely. Our systems can be configured for your specific needs with different part-feeding solutions, tending bases, a wide range of grippers, auto doors, plug-and-play vise actuators and more.

Benefit from a Turnkey CNC Machine Tending System

Cobot Systems’ CNC machine tending cobots feature all the functionalities you need to automate your workflows quickly and safely. Our systems can be configured for your specific needs with different part-feeding solutions, tending bases, a wide range of grippers, auto doors, plug-and-play vise actuators and more.

Create an Engaging Production Environment for Your

Expert Machinists—and Keep Them Working for You!

Investing in a CNC machine tending cobot is not only good for your bottom line, it’s a great way to help your

machinists learn new skills, work on more stimulating aspects of their jobs, and improve job satisfaction.

All this while winning more customers with quality and fast throughput.

Xcelicut Story:

From integration to production in 1 day

thanks to Cobot Systems

Röchling Industrial Story:

30% Production Increase with this CNC

Machine Tending Cobot System

How to Choose a CNC Machine Tending Robot?

When choosing a CNC machine tending robot, several factors must be considered

to ensure you make the right decision based on your specific needs.

1.

Evaluate the tasks the robot will perform along with the weight and size of the components it needs to handle. This will help determine the robot’s payload and reach requirements.

2.

Consider the cycle time or production speed to ensure the robot can keep up with the pace. When speaking to vendors, inquire about precision and repeatability performance levels and safety features to safeguard your staff.

3.

Ask for a demo to see how easy the CNC machine tending robot is for setup times, operation, and maintenance.

4.

Compare post-sale technical support packages.

We get it. Diving into Automation can be complicated. Not with Cobot Systems.

Are you worried that implementing a CNC machine tending cobot will disrupt production, cause pushback from operators, and affect consistency? Let Cobot Systems’ CNC machine tending specialists demonstrate how investing in advanced machine tending robots will elevate your operational efficiency. Your machinists will come to recognize how advantageous automating dull tasks can be.

Lets Discuss Your Automation Needs

Frequently Asked Questions

Which robot is used for machine tending operations?

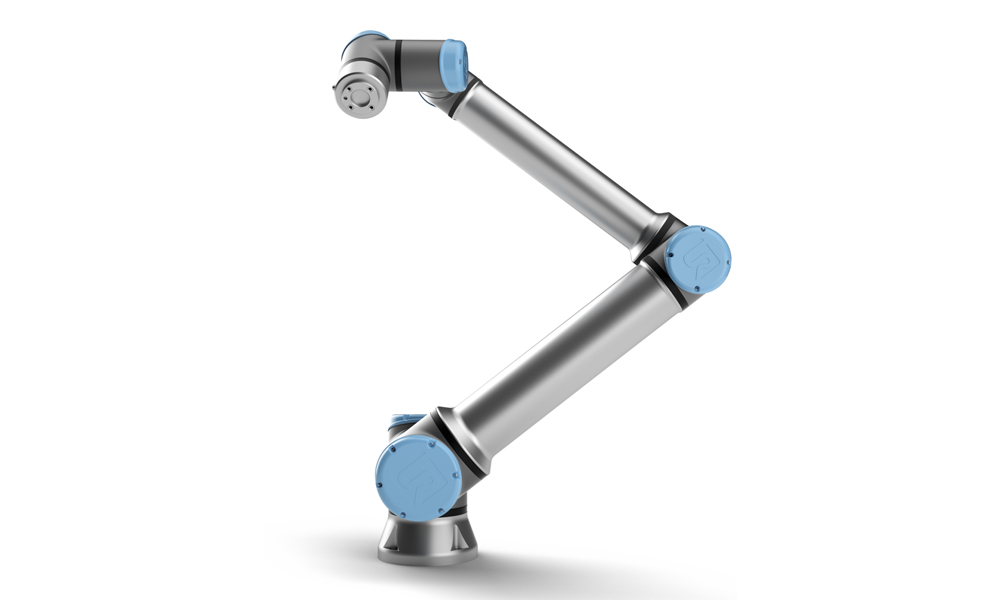

Different types of robots can be used for machine tending operations, but the most common ones are industrial articulated cobots. Many manufacturers opt for CNC machine tending cobots because of their small shop floor footprint, ease of use, flexibility, precision, and ability to handle a wide range of tasks.

What is a machine tending robot?

A machine tending robot or cobot is a robotic system designed to operate CNC machines, lathes, injection molding machines, presses, and other types of machinery. A CNC machine tending cobot loads raw materials into a machine unloads finished parts, and even performs quality checks. These CNC machine robots enhance productivity, reduce labor costs, and increase operational safety.

What is CNC machine tending?

CNC machine tending is the process of overseeing and managing a Computer Numerical Control (CNC) machine. This involves loading the machine with raw materials, unloading finished parts, and ensuring the machine operates smoothly. The process can be manual, semi-automated, or fully automated using CNC machine tending robot or cobot solutions.

Can a CNC machine be considered a robot?

While a CNC machine and a robot share some similarities, such as the ability to automate tasks, they are different. A CNC machine is guided by computer-programmed commands and is designed to carry out specific tasks like cutting, milling, or turning. On the other hand, a robot, especially an industrial robot, is more versatile and can perform various tasks, including tending to CNC machines. So, a CNC machine can’t be considered a robot, but a robot can be used to operate a CNC machine.