Cobot Systems

Affordable Automation.

Integration Included.

Start solving your labor challenges today.

Get Affordable

Standard

Automation

Expand Your

People Power

Maximize

Your Profits

Featured Cobot Systems

Solving Your Application With Standardized Cobot Systems

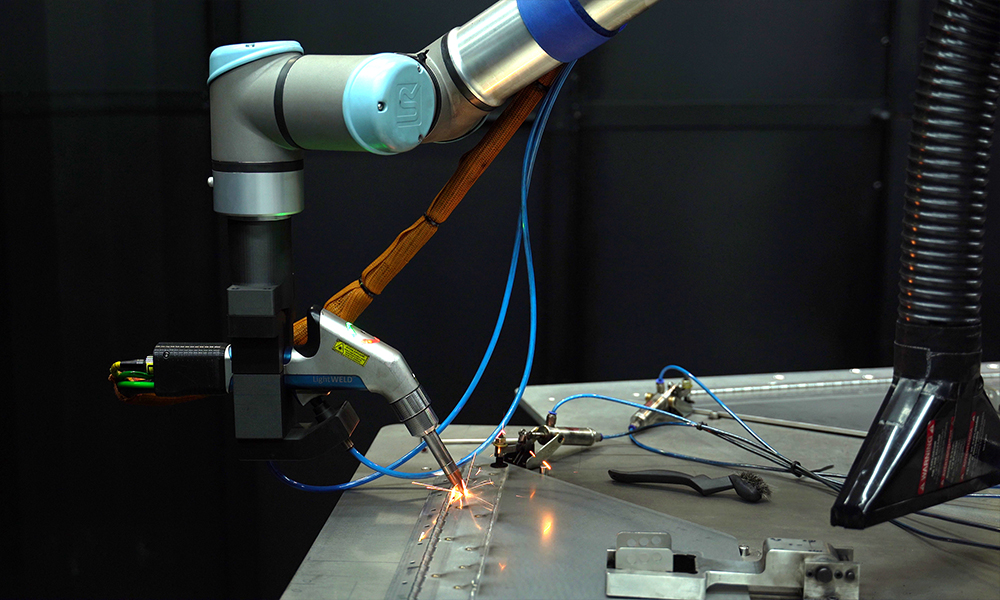

Laser Welding Cobot System

Machine Tending Cobot System

Palletizing Cobot System

Let your people focus on what’s important and leave the dull, dirty, and dangerous tasks to cobots—This is how to solve your labor challenges.

Solving Your Application

w/ Standardized Cobot Systems

Laser

Welding

Machine Tending

Cobot Systems

Palletizing

Injection

Molding

Screwdriving

Dispensing

Solving Your Application

With Standardized Cobot Systems

1

Start

Automating

2

Empower

Employees

3

Strengthen

your Team

Solving Labor Shortage with

Standard Cobot Solutions

Automation of production machinery should not require costly, complicated, and time-consuming integration. There should be no additional cost to prepare a second or third machine to communicate with a robot you may want to move around your shop.

Our experienced team has closely analyzed the cumbersome and sometimes frustrating process of integrating and validating robot-to-machine communications and studied the natural human-to-machine interactions to develop highly effective, efficient cobot systems.

It’s simple. Just plug and produce!

We offer standardized solutions for CNC Machines, press brakes, injection molding, palletizing, welding, bagging, testing, and assembly, including torque-controlled screw-driving and fluid dispensing for sealing and adhesive applications.

Let’s Discuss Your Automation Needs