Having a laser welder in your shop can significantly improve the weld quality and productivity for many applications. However, not every laser welder will work for your parts and production processes.

This guide will help you understand if laser welding is right for you, what options there are, how to apply it, and why automating laser welding with a cobot can be a game changer.

How Laser Welders Work

Regardless of the laser welding type, all lasers use a focused light beam to melt and fuse the welded material. Fiber lasers use an optical fiber doped with rare-earth elements to produce an extremely high power output with a highly precise beam. While they can be hand-held, not all are. Typically, fiber lasers (as CO2 and other laser welding types) are controlled by a robot or a CNC machine.

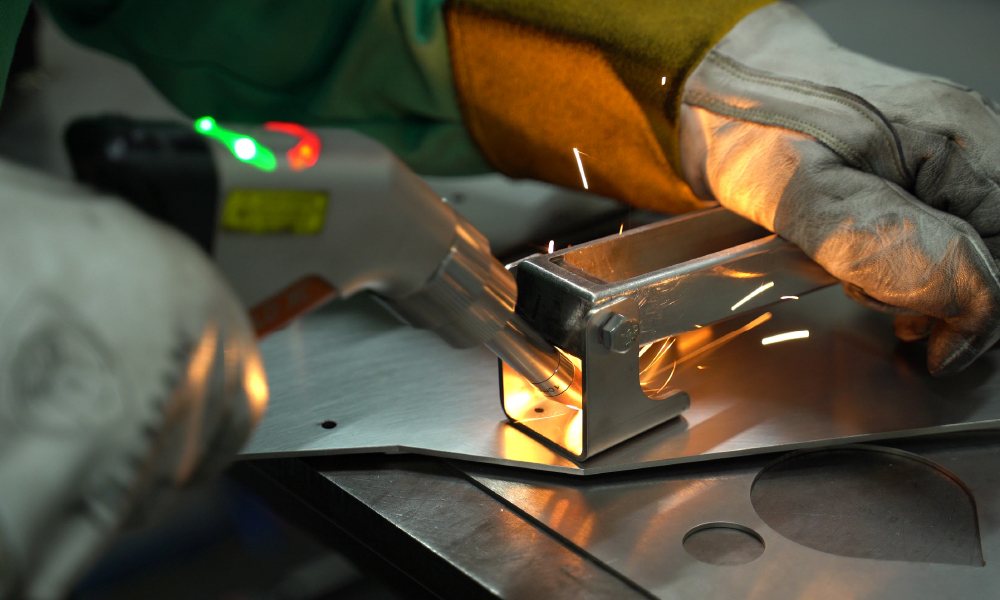

However, most small to medium-sized manufacturers are more likely to benefit from handheld fiber laser welders, as shown in the image below.

Is Laser Welding Worth It?

Laser welding is most definitely worth it if you weld thin gauge materials like sheet metal. While laser welding equipment is more costly than TIG, it can quickly pay itself off thanks to much higher productivity and reduced rework and scrap. Likewise, your operators won’t need specialized skills to use laser welding on day one, with the right laser welding system.

Laser Welding Equipment

Fiber laser welding needs a shielding gas and can work with or without a filler metal wire. A handheld fiber laser welding setup has:

• Laser welding gun with consumables like focus lens, protective lens, and nozzles.

• Power source

• Shielding gas (argon or nitrogen)

• Workpiece clamp (for safety only)

• Safety laser enclosure with interlocks.

• Safety laser welding glasses and a laser welding helmet.

• Optional wire feeder that automatically feeds the filler metal into the laser’s path and the weld joint.

How expensive are laser welding machines?

Depending on the brand and type, the laser welder costs can vary between $10,000-100,000 for mid-range equipment and up to $1M or more for industrial-grade laser setup. The handheld fiber laser welder costs about $20,000-40,000, while the cobot laser welding system costs about $150,000.

Laser Welding Brands

Multiple manufacturers provide high-end laser welding equipment for various laser welding types.

1. IPG Laser Welders

IPG Photonics is a USA brand and a leader in the laser welding space, especially in the handheld fiber laser niche. Their IPG LightWeld model is highly simplified to the point where you can just pick it up and make astonishing welds in just a few hours of training. Much training is about laser welding safety, as the welding process is straightforward.

Besides simplicity, Cobot Systems integrated the IPG LightWELD into the automated Laser Welding Cobot System because of extreme weld quality. You may also see some brands selling IPG’s handheld fiber laser unit under a different brand name with some modifications (white label).

2. Amada Weld Tech

Amada Weld Tech is another US-based giant in the industry of laser welding. They provide various types of industrial laser welders, including fiber laser welding equipment. Amada laser welding machines are more suited for high-capacity and high-precision production.

3. Trumpf

Trumpf Group is a large German brand with a long history in the laser welding world. Trumpf laser equipment ranges from CO2 to fiber lasers with small, automated cells and large units for high production capacity. Their machines can cut, weld, mark, and process surfaces with laser, depending on the application and the used material.

4. Lasermach

Lasermach is a Belgian brand offering laser welding equipment, including handheld fiber laser welding. Like IPG’s handheld laser, their system can weld various materials manually, automated, and with or without the wobble function.

Fiber Laser Welding Benefits

Whether manually or automated, fiber laser welding offers many advantages over arc welding processes. With the right system, like the IPG LightWELD, you can significantly improve productivity, profits, and weld quality, while reducing costs and operator training requirements.

• 4X faster than TIG.

• Same or better weld quality than TIG.

Exceptionally easy to learn; you can weld on the same day.

• Very simple to automate (with the right system).

• High energy efficiency. Low energy loss to HAZ.

• Deep, narrow penetration.

• Low heat input and narrow HAZ.

• Minimal distortion.

• Exceptional weld appearance and smoothness.

• Little to no post-welding processing.

• Welds almost all materials, including dissimilar metals (e.g., aluminum to copper).

• Laser welding strength is typically higher than conventional welding methods.

• Reduced negative metallurgical effects from heat input.

• Filler wire is optional. You can weld autogenously.

• More flexibility and weld joint design freedom than arc welding.

• Most metals require nitrogen shielding gas, which is less costly than argon.

• No burn-through and warping with sheet metal.

Fiber Laser Welding Applications

Laser welding applications are primarily limited by the thickness and the weld preparation. You can typically weld thicknesses up to 1/4-inch with a hand-held fiber laser. It’s also necessary to have as good edge/bevel quality as possible for high laser accuracy. Some laser power sources, like the one from IPG, can wobble the laser dot, reducing the need for highly precise joint fit-up.

• Almost all sheet metal applications

• Aerospace

• Defense

• Medical

• Food and beverage

• Automotive

• Transportation

• Tube and pipe welding

• HVAC

• Architecture

• General manufacturing

You can laser weld stainless steel, carbon steel, nickel alloys, titanium, copper, aluminum, and galvanized steel, covering almost every material in most industries.

Automating Laser Welding With a Cobot Gives You Significant Advantages

Manual laser welding works well, but automating it with a cobot gives you the best of both worlds. You get the flexibility of manual operation with robotic precision and repetition. Almost any part that can be hand welded can be produced with a good cobot system.

Unlike manual, robotic laser welding always has the same speed, laser gun manipulation, and finished weld appearance and quality. However, the biggest advantage of cobot welding is a boost in productivity without necessarily hiring additional welders.

Traditional robots are difficult and time-intensive to program. You will need just a few minutes to teach a repetitive batch to the Laser Welding Cobot System, not hours or days. Likewise, it uses intuitive no-code software that operators can quickly learn to use. So, no costly downtime or training is required.

A perfect example of what’s possible with the right system comes from the QTR Industries. Upon implementing the Laser Welding Cobot System, QTR reduced their welding time from 90 minutes to just 10 minutes per piece!

Ready For Laser Welding?

Get our laser welding ebook to learn the ins and outs of the process and see if your production is suitable for it. Reach out, and we’ll help you decide if manual or cobot laser welding suits your processes the best.