Laser welding stainless steel is much easier than arc welding processes like TIG and MIG. But more importantly, the process is way faster and produces the same or better weld quality.

For sheet metal and thicknesses up to 1/4 inch (sometimes thicker), laser welding is the best welding process for most stainless steel applications.

Challenges Of Welding Stainless Steel

Regardless of the welding process you use, you’ll face these stainless steel welding issues. However, laser welding can reduce or nearly eliminate most of them.

• Excessive heat affected zone (HAZ)

• Weld discoloration and oxidation

• Distortion

• Loss of Corrosion Resistance

• Weld zone and HAZ embrittlement

• Hot Cracking

The bulk of the issues with all stainless steel welding come down to the material’s low tolerance for heat and the difficulty of traditional welding processes to limit the heat input. This is precisely where laser welding excels. Switching from arc welding to laser will significantly improve the part quality for most production welding jobs.

Types of Stainless Steel

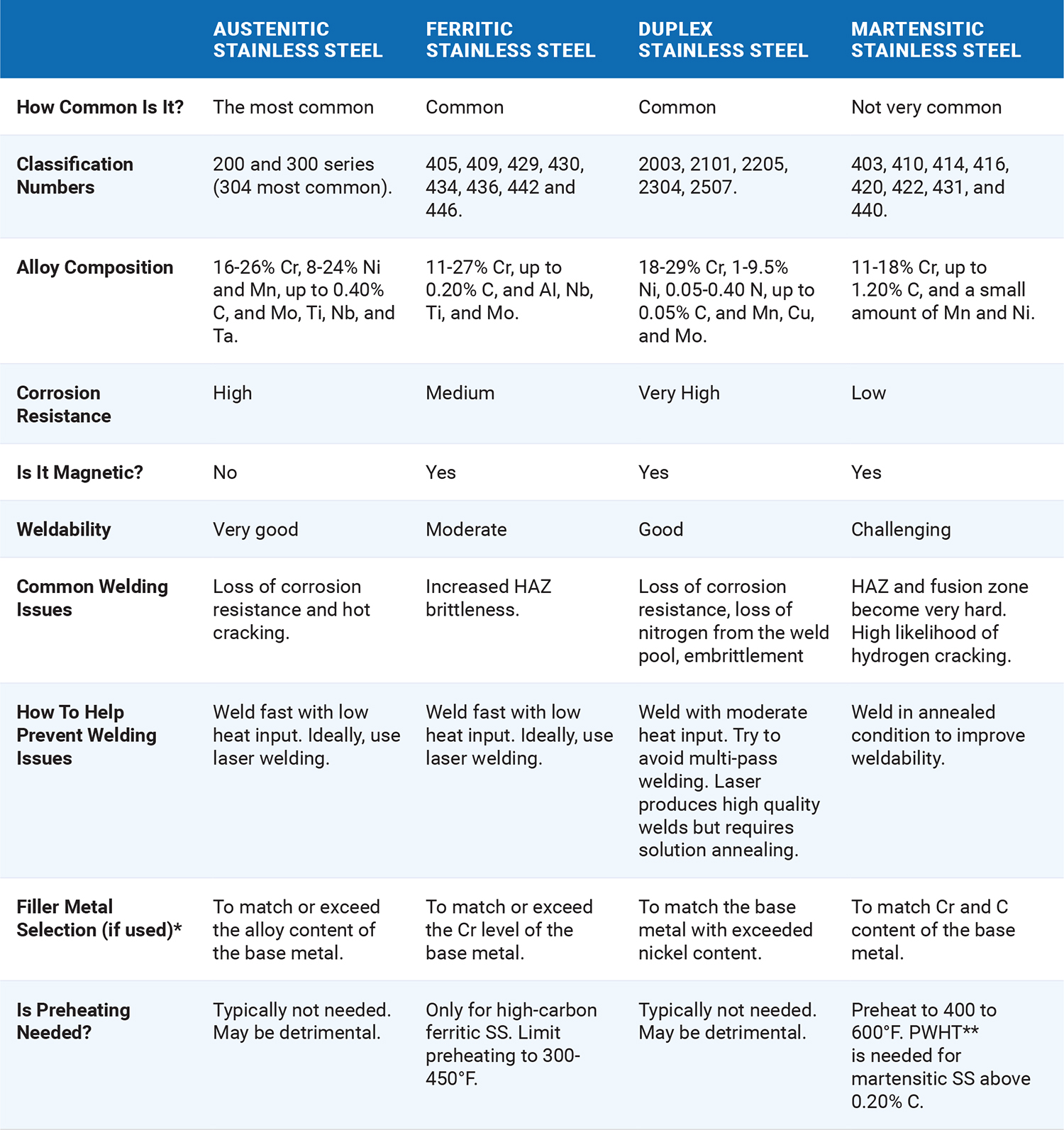

Weldability Of Different Stainless Steel Types

* This is a generally recommended filler metal. Service conditions can affect the actual selection.

** PWHT = Post Welding Heat Treatment.

The table above outlines the different weldability issues and solutions for most types of stainless steel. However, since austenitic stainless steel is the most widely used in the industry, we’ll focus on it alone in the rest of the blog.

Benefits of Laser Welding Stainless Steel

Laser welding stainless steel is one of the best ways to improve productivity, weld quality, and profits. It’s a welding technology that surpasses arc welding in many applications and by most criteria.

High Productivity And Welding Speed

A Handheld laser welding system welds 4X faster than manual TIG (check out our laser vs TIG welding comparison). Lasers’ speed doesn’t just improve productivity but drastically reduces the HAZ and negative metallurgical changes due to excessive heat input.

One less commonly considered productivity gain with laser is just how quickly you can handle the part after welding. Of course, you should practice every precaution and workplace safety measure. However, laser-welded components can generally be handled quickly upon welding, compared to TIG, where you have to wait at least 20 minutes.

There’s even more opportunity to boost welding output with laser welding. If you use a Laser Welding Cobot System, you can drastically scale your welding operations while eliminating most welding defects.

Minimize or Eliminate Distortion

Stainless steel retains heat much better than mild steel. It won’t dissipate heat quickly into the air and the surrounding metal. So, when you TIG or MIG weld stainless steel, the heat input accumulates as you progress along the joint. As a result, traditional welding processes can distort the material and make it difficult to meet customer-defined tolerances.

Laser welding can almost eliminate distortion in most applications. Laser’s heat concentration into a tight dot and high welding speed minimize HAZ and reduce heat buildup.

Preservation Of Corrosion Resistance

Have you ever seen stainless steel tanks or similar equipment with corrosion along the weld zone? That’s not supposed to happen, right? But sometimes it does.

Austenitic stainless steel may not be so “stain-less,” if kept at its sensitization temperature (800-1650°F) during welding. This causes carbide precipitation, a process where chromium forms chromium carbides with carbon, leading to possible corrosion issues. Chromium is responsible for stainless steel corrosion resistance, so its depletion (due to binding with carbon) causes intergranular corrosion along the weld zone.

All arc welding processes, especially TIG, can produce too much heat during welding, which can cause intergranural corrosion. This can be a costly welding defect if the weld fails in service condition due to corrosion.

Laser welding significantly reduces the heat input, almost entirely eliminating the risk of carbide precipitation and the loss of corrosion resistance.

Excellent Weld Quality And Precision

Laser welding produces exceptionally clean, smooth, and precise welds on stainless steel. Only TIG welding can come close to laser weld quality. But, TIG can never provide such a low heat input as the laser. And with pulsed laser welding, you can easily stack dimes just like with TIG.

Besides extremely narrow HAZ, laser welding can achieve very deep penetration with an excellent width-to-depth ratio. On the other hand, with wobble laser welding, you can widen the weld pool to an extent, ensuring a sound weld with a more lax fit-up.

Non-contact Welding

Laser welding is a non-contact process. Similarly to how tungsten electrode with TIG never touches the work piece (HF TIG), laser welding doesn’t make direct contact. However, unlike TIG, a laser welding gun doesn’t have an electrode that can erode and contaminate the weld or affect the arc quality.

The laser welding beam is a highly focused beam of light coming from the tip of the laser gun. The light itself melts the parent and filler metal (if used with a wire), so laser eliminates the risks associated with the electrode (like with TIG).

Note: the laser welding gun must touch the welded metal for safety reasons. But this is irrelevant to the welding process.

You Can Save On Shielding Gas

Our fiber laser welding equipment requires a nitrogen shielding gas for stainless steel. This is a big advantage over TIG/MIG because nitrogen is less costly than argon (TIG) and tri-mix (MIG) gasses. Shops can also generate their own nitrogen and avoid buying gas altogether.

Laser Welding Stainless Steel Is Extremely Simple

Stainless steel is a very tricky material. It’s more sluggish than mild steel and retains more heat. Only an experienced welder can make high-quality welds with TIG or MIG on stainless steel. But laser welding is here to change that.

Laser welding is almost entirely simplified to adjusting a few settings on the machine and just traveling along the joint. Whenever someone is first introduced to handheld laser welding, there’s always that initial amazement at just how easy it is. A complete beginner can make a sound laser weld on stainless steel with less than a day of training. It’s that simple.

The laser’s ease of use is highly beneficial in today’s tight labor market. Welder shortage makes it difficult to scale your business. But with laser, you can hire less experienced welders because the process doesn’t require significant experience, like TIG. And your operators will massively boost output compared to TIG.

Laser Welding Is Easy To Automate

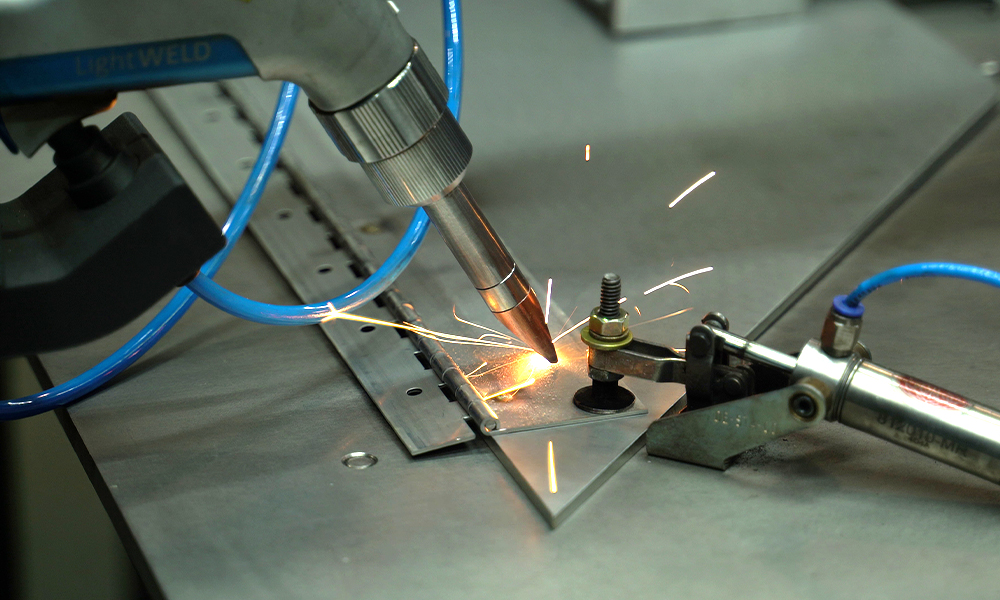

Manual laser welding is great, but automated is much more productive. If your shop often makes 10-200 part batches that have mixed shapes and sizes, you can drastically boost your welding output with a suitable welding cobot.

Our no-code programming Laser Welding Cobot System lets your welding operator do more and nearly eliminate rework. And since laser welding is a fairly simple process, setting up the welding parameters and torch positioning on a cobot is faster and easier than comparable processes like TIG.

To program a part with our Laser Welding Cobot System, all you need to do is:

1. Guide to cobot’s arm by moving it with your hand.

2. Adjust the weld parameters on the teach pendant using intuitive software.

3. Click start to let the cobot weld.

The UR Cap Software, included with the cobot, requires minimal training. The software use revolves mainly around setting up the laser weld parameters and torch positioning. You don’t need to hire robotic technicians or programmers, your existing staff can quickly learn to use the cobot.

Take Your Production To The Next Level

Download our free eBook on laser welding to learn more, or if you feel ready, reach out to discuss your fabrication needs with our team. Your business size doesn’t matter. Laser welding systems can help small, medium, and large manufacturers.

Laser Welding Stainless Steel FAQ

Is laser welding stronger than TIG?

Laser welding can be stronger than TIG because it produces minimal HAZ and is less likely to cause negative metallurgical changes in the weld and HAZ.

What is the disadvantage of laser welding?

The main disadvantage of laser welding is the limited thicknesses you can weld in a single pass for full penetration welding. Our laser welding systems can weld up to 1/4-inch thick stainless.

Is laser welding expensive?

Laser welding cost requires a higher initial investment than arc welding equipment. But it can quickly pay itself off thanks to lasers’ immense welding speed and exceptional weld quality.

Can I weld dissimilar metals using laser welding?

Yes, laser welding can join stainless steel to dissimilar metals. But, you must carefully consider the material compatibility and application to ensure the part can meet the requirements.