Resources

Learn more about automation and cobots and explore our client case studies!

Robotic TIG welding improves welding consistency, quality, and productivity. However, TIG (GTAW) requires more skills than other welding processes and has numerous challenges, even with robots in the picture. The TIG welding process can produce high-quality welds on... Is it possible to cut your welding time on a specific part from 90 minutes to 10 minutes? That’s exactly what Quality Tooling and Repair (QTR) achieved with help from Cobot Systems. This case study explains how QTR changed their welding processes and boosted... Laser welding vs. TIG welding is a hot topic for a good reason. Manual and automated laser welding equipment have become more accessible, challenging TIG’s reign as the go-to process for high weld quality. The TIG welding process has seen incredible development in the... Xcelicut Precision Machining faced a familiar challenge that many small machining shops encounter: finding laborers to do the monotonous job of loading and unloading CNC machines. With a small team of five, including owner Will Fennell, Xcelicut needed a solution that... Prices can range from $2,500 to $10,000 for basic models suitable for amateur use, around $21,000 to $25,000 for manufacturer-grade systems, and up to $150,000+ if paired with a robotic. Factors influencing the cost include the brand, power of the system, and... What do you do when faced with labor challenges and tedious tasks? With labor shortages and the repetitive nature of machine tending, many manufacturers struggle to maintain productivity and employee satisfaction. Röchling Industrial, a key player in the machining of... In a world where productivity and efficiency reign supreme, plant managers, production managers, and welding engineers constantly grapple with the challenge of selecting the most effective welding method, MIG or TIG. Both have their strengths and weaknesses, but the... The landscape of manufacturing is evolving with the introduction of groundbreaking technologies. At the forefront of this evolution are IPG Photonics Corp. and Cobot Systems, who are reshaping the way we approach welding. Their collaboration, enhanced by Universal... Cobots DemystifiedPractical, hands-on solutions for manufacturersTDO (Train, Develop, Optimize)445 Electronics Pkwy #102Liverpool, NY 13088Thursday, June 13th, 202410:30am - 3:00pm ESTWe're hosting a hands on cobot workshop at TDO (train, develop, optimize)!Join NEFF... FOR IMMEDIATE RELEASE5/14/2024North Versailles, PA - May 14th, 2024 Cobot Systems proudly announces that it is now a UR+ Partner with their showcase Laser Welding Cell system. This distinction marks a significant milestone in the company's journey to provide automated...

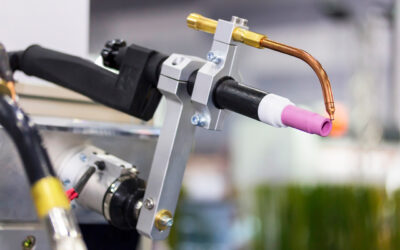

5 Common Robotic TIG Welding Issues (with Solutions & Alternatives)

How QTR Improved Welding Efficiency with Cobot Laser Welding

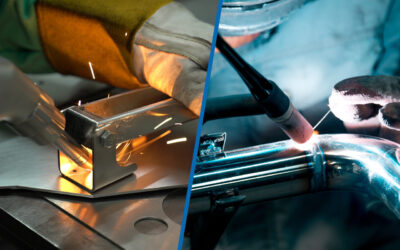

Laser Vs. TIG Welding: An Unbiased and Objective Comparison

Xcelicut’s Success Story: Improving CNC Operations with Cobot Systems

How Much Does a Laser Welder Cost?

How Röchling Industrial Increased Production by 30% with Cobot Systems

Mig vs. Tig Welding – What Are the Differences and How To Automate the Process

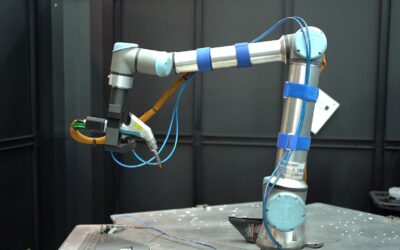

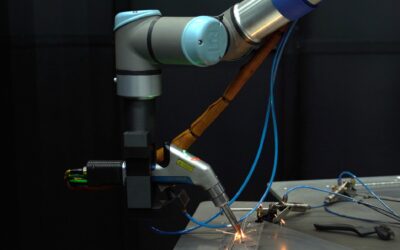

Super Cell: Handheld Laser Welding Technology Meets Robotics

Cobots Demystified

Cobot Systems Announces UR+ Partnership with its Laser Welding Cobot

Robotic TIG welding improves welding consistency, quality, and productivity. However, TIG (GTAW) requires more skills than other welding processes and has numerous challenges, even with robots in the picture. The TIG welding process can produce high-quality welds on... Laser welding vs. TIG welding is a hot topic for a good reason. Manual and automated laser welding equipment have become more accessible, challenging TIG’s reign as the go-to process for high weld quality. The TIG welding process has seen incredible development in the... Prices can range from $2,500 to $10,000 for basic models suitable for amateur use, around $21,000 to $25,000 for manufacturer-grade systems, and up to $150,000+ if paired with a robotic. Factors influencing the cost include the brand, power of the system, and... In a world where productivity and efficiency reign supreme, plant managers, production managers, and welding engineers constantly grapple with the challenge of selecting the most effective welding method, MIG or TIG. Both have their strengths and weaknesses, but the... The landscape of manufacturing is evolving with the introduction of groundbreaking technologies. At the forefront of this evolution are IPG Photonics Corp. and Cobot Systems, who are reshaping the way we approach welding. Their collaboration, enhanced by Universal...

5 Common Robotic TIG Welding Issues (with Solutions & Alternatives)

Laser Vs. TIG Welding: An Unbiased and Objective Comparison

How Much Does a Laser Welder Cost?

Mig vs. Tig Welding – What Are the Differences and How To Automate the Process

Super Cell: Handheld Laser Welding Technology Meets Robotics

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.No Results Found