Are you considering automating your sheet metal fabrication with laser welding cobots? These advanced systems can increase productivity and improve quality while keeping costs manageable.

But how do you know if the investment is worth it? Understanding the return on investment (ROI) is key.

In this blog, we will consider the financial and operational benefits of laser welding cobots, helping you evaluate their impact on your shop floor and ensuring your investment drives substantial gains.

Why Manufacturers Choose Laser Welding Cobots

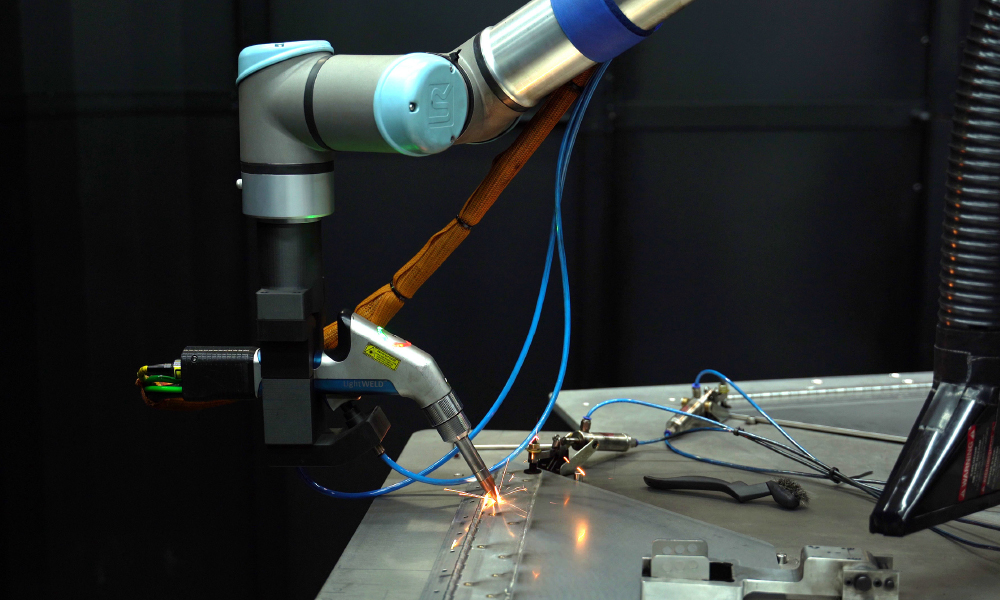

Laser welding cobots have become a go-to solution for manufacturers looking to raise the bar in efficiency and consistency.

These robotic systems deliver precision and reliability that set new standards in manufacturing. They streamline the welding process, ensuring each weld meets stringent quality requirements without compromise.

Compared to traditional methods, laser welding cobots offer significant advantages in terms of speed, consistency, and operational costs.

Factors Influencing ROI

Before diving into the specifics of ROI, let’s break down some key factors that contribute to the financial considerations of implementing laser welding cobots in sheet metal fabrication.

Fixed Costs

When investing in laser welding cobots, there are some upfront expenses that play a role in determining ROI:

• Initial investment: This includes the cost of purchasing the laser welding cobot itself along with necessary accessories to optimize its performance.

• Installation and setup expenses: This step ensures the workspace is configured for cobot integration, which may involve modifications and adjustments.

• Safety equipment and compliance costs: Essential items that may be needed such as barricades or cages for meeting regulatory standards and ensuring a safe working environment.

Variable Costs

On the operational front, variable costs associated with laser welding cobots include:

• Operational expenses: These expenses include energy consumption and ongoing maintenance to keep the cobot running efficiently.

• Consumables: Such as laser gases, optics, and replacement parts needed to maintain peak performance.

• Training and ongoing support costs: Ensuring welders are adequately trained to operate and maintain the cobot, along with ongoing support to address any operational challenges.

These factors collectively impact the overall ROI of integrating laser welding cobots into sheet metal fabrication processes.

ROI Calculation

Typically, the overall investment in a laser welding cobot system can be around triple the initial cost of the cobot itself. However, the ROI period can vary significantly, often ranging from 18 to 24 months, depending on factors like operational efficiency gains and cost savings.

For a more precise assessment, tools like the Robotics ROI Calculator can help manufacturers estimate potential returns based on their specific operational parameters and financial projections.

Example Calculation:

Let’s consider a hypothetical scenario:

• Initial Investment: $150,000 (includes cobot and necessary accessories)

• Annual Labor Cost Savings: $50,000

• Annual Scrap Reduction: $20,000

• Annual Maintenance Cost: $10,000

• ROI Period: Estimated at 24 months

In this scenario:

• The initial investment of $150,000 covers the purchase of the laser welding cobot, necessary setup modifications, and initial training costs.

• Annually, the cobot reduces labor costs by $50,000 through increased productivity and efficiency. This results from faster welding cycles and reduced reliance on manual labor.

• Scrap reduction due to improved weld quality saves an additional $20,000 annually.

• The annual maintenance costs for the cobot amount to $10,000.

Based on these figures, the total annual savings and cost reductions amount to $80,000. With an expected ROI period of 24 months, the manufacturer would recoup the initial investment within two years.

Beyond that, the laser welding cobot continues to generate substantial savings and efficiencies, significantly improving profitability for the business. This example demonstrates the tangible financial benefits of investing in laser welding cobots for sheet metal fabrication.

4 Benefits That Increase Your ROI

Investing in laser welding cobots for sheet metal fabrication offers a range of benefits that directly contribute to improved ROI and operational efficiency.

1. Better Productivity

Laser welding cobots significantly improve productivity by increasing throughput and reducing cycle times. Compared to manual welding, cobots can operate continuously without breaks, leading to faster production cycles and higher output volumes.

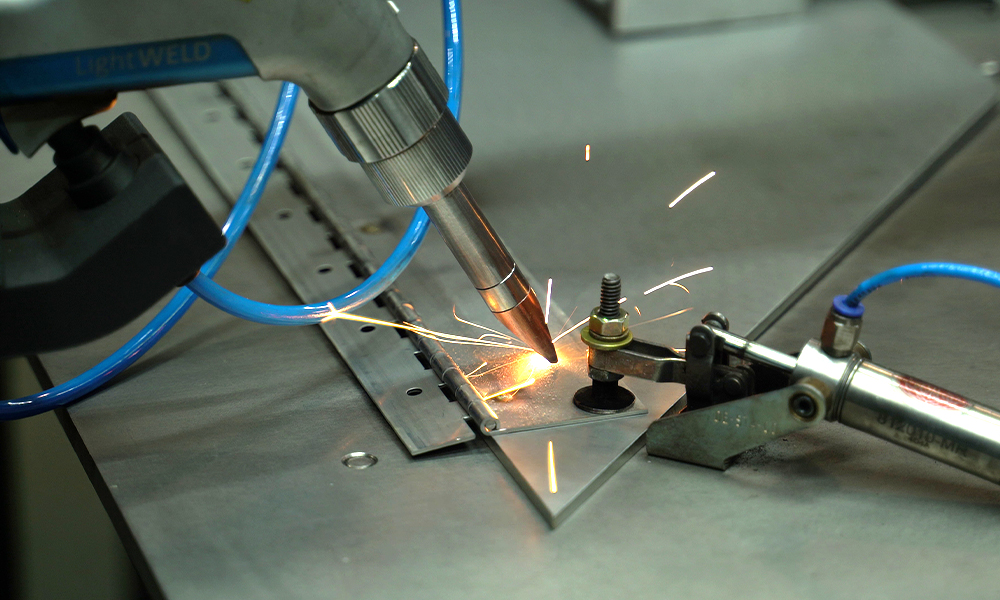

2. Improvements in Quality

One of the key advantages of laser welding cobots is their ability to consistently deliver high-quality welds. This results in lower scrap rates and improved weld consistency across production batches. By minimizing defects and ensuring precise welds, manufacturers can reduce material waste and improve product quality.

3. Labor Efficiencies

Automating welding tasks with cobots frees up skilled labor from repetitive and physically demanding welding operations. This allows personnel to focus on higher-value tasks such as process optimization, quality control, and innovation. As a result, workforce productivity increases, and labor costs associated with manual welding are reduced.

4. Scalability and Flexibility

Laser welding cobots allow you to adapt quickly to changing production demands. Whether scaling up production to meet increased orders or adjusting to variations in product specifications, cobots can be programmed and reconfigured efficiently. This agility helps manufacturers maintain competitiveness and responsiveness in dynamic market conditions.

These benefits collectively contribute to a significant return on investment that allows sheet metal fabrication businesses to achieve operational excellence and sustainable growth.

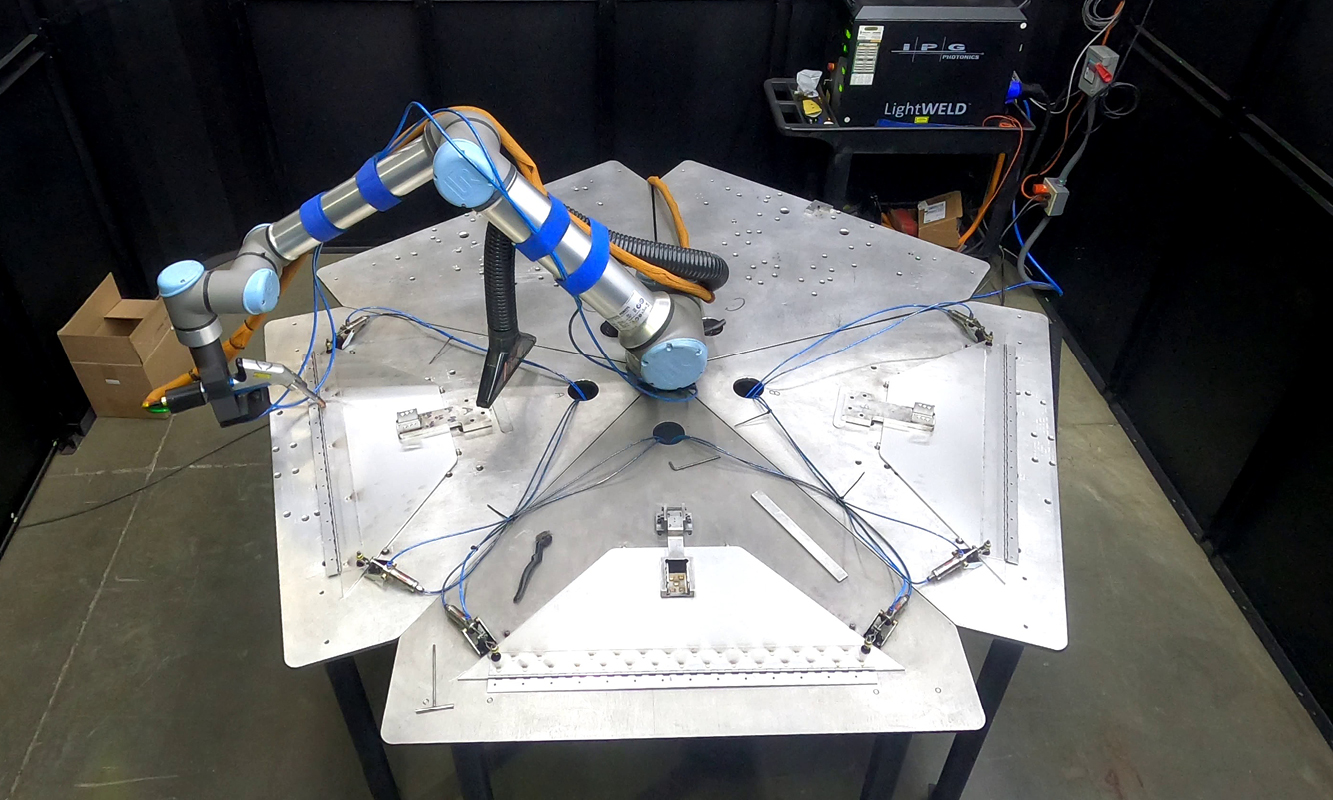

Case Study: Real-World Application

In a real-world scenario, QTR Industries integrated laser welding cobots from Cobot Systems to improve their metal fabrication processes. Their success story shows how it is possible to boost welding efficiency and cut operational costs while upholding top-notch quality standards.

Key Highlights from the QTR Case Study:

QTR Industries faced challenges with manual welding methods, such as inconsistent weld quality and labor-intensive operations. By adopting Cobot Systems’ laser welding cobots, they achieved remarkable results:

• Improved efficiency: The cobots allowed QTR to ramp up welding speed and decrease cycle times, streamlining production.

• Quality assurance: Leveraging precise laser welding capabilities, they achieved consistent weld quality, leading to fewer defects and increased product reliability.

• Labor optimization: Automating with cobots allowed QTR to redeploy skilled workers to more strategic roles, boosting overall workforce productivity.

By implementing laser welding cobots, QTR Industries reduced operational costs and improved their competitive standing in the industry. This case study exemplifies how advanced automation technologies can tangibly improve productivity, quality, and operational efficiency across metal fabrication businesses.

Driving Growth with Laser Welding Cobots

Adopting laser welding cobots in sheet metal fabrication offers compelling advantages in productivity, quality, and operational flexibility. The potential for significant ROI through improved efficiencies and reduced scrap rates makes it a strategic choice for manufacturers.

The versatility of laser welding cobots will improve your operational capabilities and position your business for sustained growth and competitiveness in the industry.

Ready to transform your manufacturing processes?

Schedule a demonstration of Cobot Systems’ Laser Welding Cobot System today and see how automation can drive your success. Contact us now to take the next step towards optimizing your sheet metal fabrication operations.