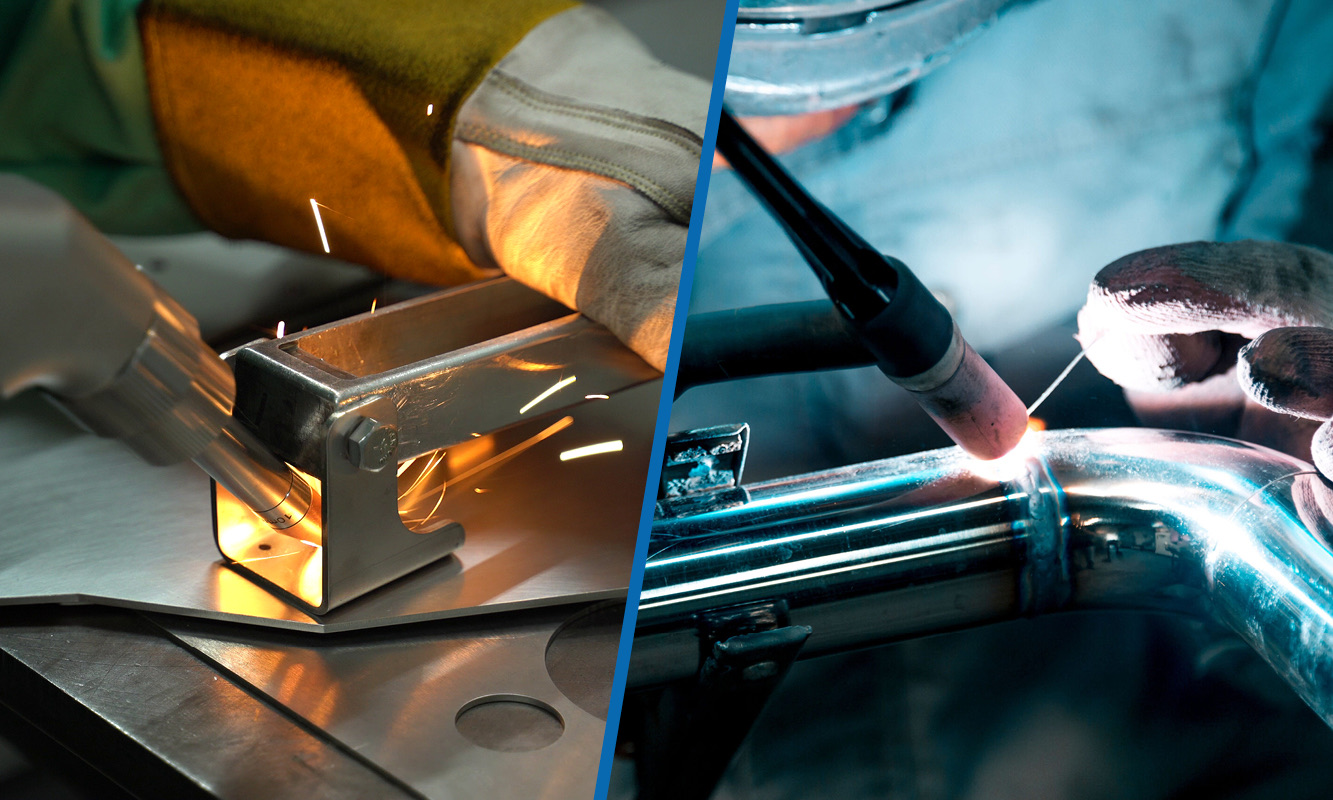

Laser welding vs. TIG welding is a hot topic for a good reason. Manual and automated laser welding equipment have become more accessible, challenging TIG’s reign as the go-to process for high weld quality.

The TIG welding process has seen incredible development in the last 80+ years. Nevertheless, it’s an aging process in a fast-paced manufacturing world where production and defect bottlenecks can’t be tolerated. Many are turning to laser welding where appropriate, as the laser has numerous advantages over TIG. However, laser can’t always replace TIG, so carefully read the comparison below to get a realistic picture of the two.

8 Differences Between Laser and TIG Welding (with Expert Insights)

TIG is an arc welding process. So, it melts and fuses the base and/or filler metal under the electric arc in a closed electrical circuit.

Laser welding, also called laser beam welding (LBW), is not arc-based. Instead, laser welding uses a beam of high-intensity radiation (laser) to melt and fuse the welded pieces.

1. Automation

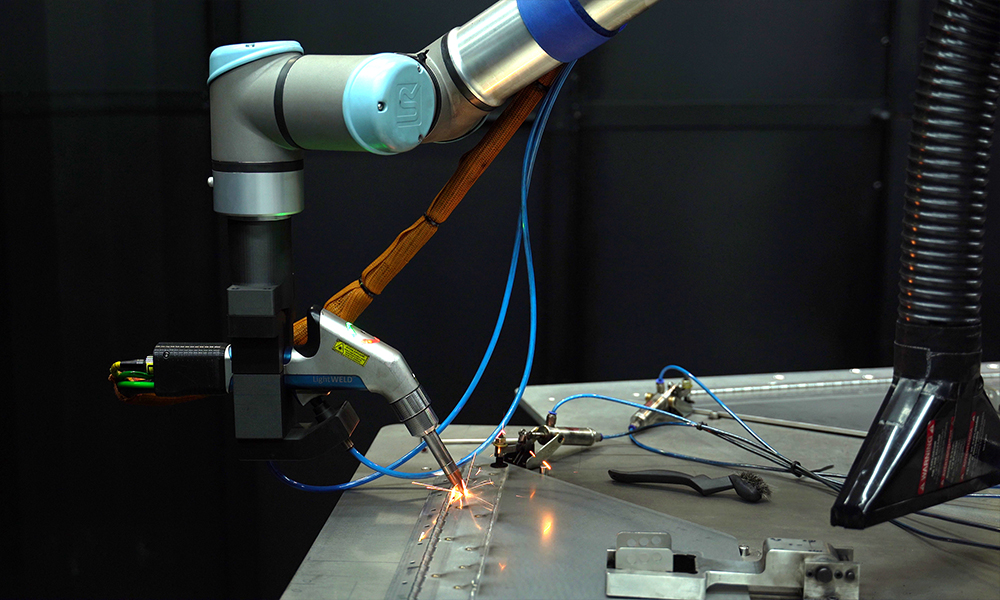

Laser welding and TIG welding processes can be automated with robots/cobots. But, laser is less challenging to automate as the process itself is far simpler.

Successfully running a robotic TIG welding setup requires TIG expertise. To use robotic TIG, you must:

- Have an In-depth understanding of TIG settings.

- Know how to set up the consumables and shielding gas.

- Have the operational know-how, like positioning the torch to the joint.

- Know how to select the TIG cup, tungsten, electrode tip shape, and torch angle for every joint type and shape.

- And more, depending on the welded metal.

Laser welding has way fewer bells and whistles, making it easier to automate. For example, even non-welders can make quality welds on the first day using our Laser Welding Cobot System.

2. Welding Speed And Productivity

Laser welding is about 4X faster than TIG welding. TIG is one of the slowest welding processes. Laser is much faster than MIG too, so the productivity gain over TIG is astronomical.

For example, the Laser Welding Cobot System has helped QTR Inc. reduce their welding time from 90 minutes per part with TIG to just 10 minutes with the laser cobot. Everyone’s mileage will vary, but laser is drastically faster than TIG.

Besides speed, laser welding improves productivity by significantly reducing post-welding work. There’s minimal soot you can wipe off easily. When required, you can also use a laser cleaning function to remove oxidation, if needed.

3. Heat Input And Distortion

Thanks to high welding speed, laser inputs far less heat into the welded piece. Laser welding technology has about 200X higher heat density than TIG per square millimeter. But, the laser’s immensely focused beam and speed prevent the heat from spreading into a wide HAZ.

TIG usually produces a large HAZ, leading to distortion, loss of edge, and degradation of the material’s properties. That’s because TIG’s arc is terribly inefficient. There is a massive energy loss that just flows into the part instead of focusing the energy where it matters—into welding.

Laser welding is the best solution to avoid distortion and edge melting when working with sheet metal. This includes spot, lap, fillet, corner, and butt welds. TIG welding a corner joint on thin sheet metal is very difficult. With laser, it’s point-and-shoot, with minimal or no distortion.

4. Autogenous And Filler Wire Welding

Both laser and TIG welding can join metal with or without a filler wire. The advantage of a laser system is reduced filler use for wire welding and simplified wire feeding.

Laser welding produces cleaner, full penetration autogenous welds, even in butt joint configuration. Likewise, wobble laser welding allows for easier utilization of the edges of the parent metal.

For example, if you overlap two metal pieces, the wobble laser function can widen the laser beam to melt the joint edges and pull in the metal for better autogenous fusion. This can be done with TIG but with much more torch manipulation effort. Laser does this automatically, while TIG requires walking the cup from edge to edge.

5. Material And Thickness Compatibility

Laser welding can join almost any material, including difficult-to-weld aluminum, titanium, nickel, copper, and stainless steel alloys.

You can also laser weld dissimilar metals with excellent results. Likewise, laser welding can join two different thicknesses with minimal distortion and no burn-through on the thinner part. It’s much more difficult and sometimes impossible to achieve the same with TIG.

Like laser, TIG can be used for almost any metal. However, TIG’s significantly higher heat input can easily lead to defects in sensitive metals like stainless steel.

Fiber laser welding can usually weld thicknesses up to 1/4-inch, depending on the metal and the power source. Material’s reflectivity determines the maximum thickness you can weld with the power output from the machine. For example, aluminum and copper require more laser power than mild steel. The primary laser welding application is sheet metal to medium-thickness welding, not working on thick plates and pipes.

TIG can weld thicker parts. A powerful TIG machine can weld 5/8-inch thick steel and aluminum. However, TIG is generally not used for heavy welding—that’s usually the job for MIG/FCAW. Still, if your application requires welding thick parts, TIG or MIG are a better choice.

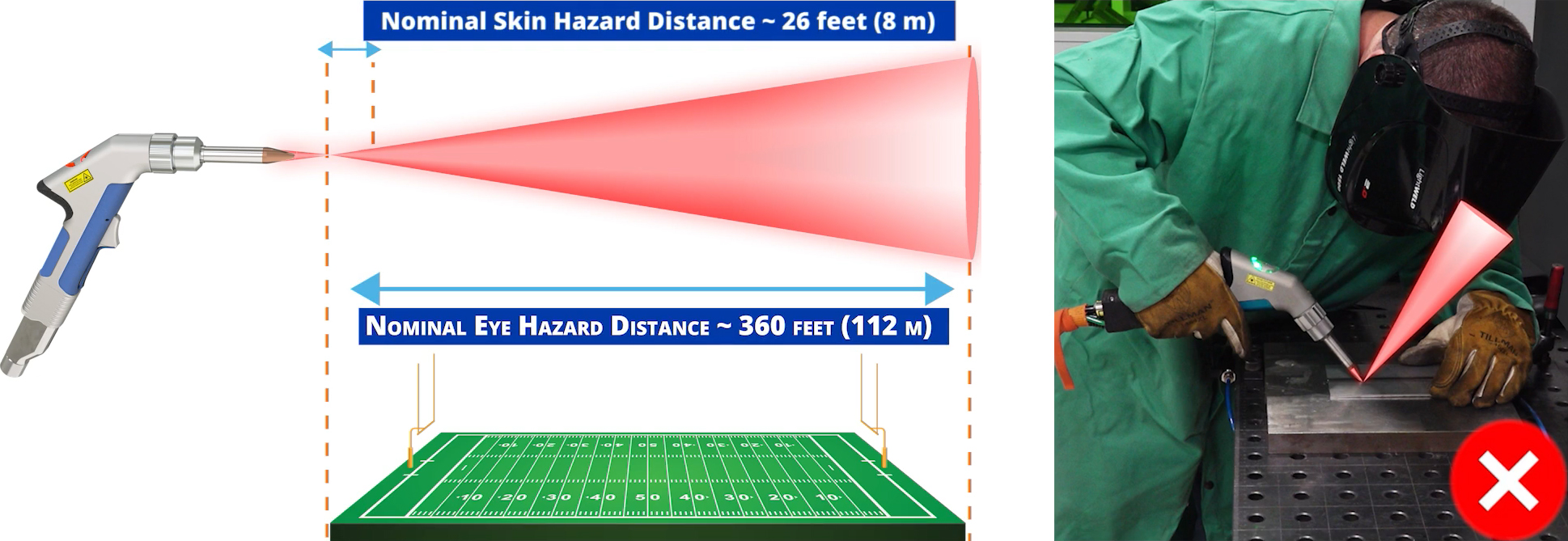

6. Safety – Laser Welding Requires a Different Approach

Laser welding safety is different than TIG safety. With lasers, the primary concern is eye hazards and burns from highly potent infrared radiation.

The most critical safety measures for laser welding are:

- Going through safety training before working with a laser system.

- Always wearing PPE for laser welding. These include laser safety glasses and a laser welding helmet (you must wear both), welding coat, and welding gloves.

- Only use the laser system in an enclosed area with safety interlocks. So, if someone without PPE accidentally opens the door, the interlock system auto-shuts down the laser.

- Never hold parts in your hand while welding.

- Positioning a gun to the joint in a way where the reflected laser beam won’t hit your body or someone else in the enclosure.

- NEVER looking directly at the laser, even with safety glasses and a helmet.

ANSI Z136.1-2022 provides in-depth guidelines on laser welding safety. However, many laser systems include the most essential safety training with the laser equipment. For example, the IPG LightWeld that’s included in our Laser Welding Cobot System requires you to take a short training course. After the completion, you get the activation code for the system, ensuring you know how to handle it safely.

Source: LightWELD Basic Operator Laser Safety Video

With TIG welding, you also must wear a welding helmet, but you don’t need to worry about reflective radiation as much. However, TIG’s arc produces UV radiation, which is a much higher risk factor for skin cancer. Likewise, UV radiation can produce Ozon, a cancerogenic compound. In general, UV radiation can modify many elements to produce poisonous or cancerous compounds. These can vary from metal cleaners to elements inside the material.

TIG poses a significant electrocution hazard. Its open circuit voltage (OCV) can be pretty high (70-80V, for example). So, if you weld with wet or sweaty hands, the skin resistance can drop significantly. Meaning, you become the path of least resistance and get shocked. Humid climates like Mississippi, Florida, West Virginia, and similar contribute to the issue, making it more likely to get shocked. This isn’t as big of a problem for robotic welding. But it’s not impossible to get shocked there too, if the wire is live and you are setting up a robot.

Laser and TIG welding have less visible fumes than MIG or FCAW. But, fumes are still there and can cause significant health hazards. So, you must use a fume extraction system with both.

7. Shielding Gas

Laser welding and TIG welding require a shielding gas to protect the weld pool from atmospheric contamination.

TIG welding almost always requires a pure argon for all metals. Sometimes, argon/helium mix can help with penetration. (E.g., welding a higher thickness than the machine allows).

Laser welding requires 100% nitrogen gas for carbon steel, stainless, copper, and nickel alloys. But, for aluminum and titanium, you need 100% argon for laser welding.

Using nitrogen is a major advantage for laser welding. Nitrogen is cheaper than argon, and you can generate it yourself with a nitrogen generator. For manufacturers, investing in a generator means never buying a shielding gas again.

8. Weld Quality

While TIG can produce quality welds, laser welding is substantially better. With drastically higher energy density, reduced heat input, and full penetration welds, laser weld quality is pushing the limits of what’s possible for conventional manufacturing.

TIG’s stack of dimes appearance is well-known in the industry. A highly skilled welder or a TIG robot operator can make impressive TIG welds. But, TIG can’t match the laser’s heat concentration, speed, HAZ narrowness, and weld quality. On the other hand, pulsed laser welding can easily produce the good old stack of dimes weld appearance. The pulsed laser mode is available with IPG power sources provided in our Laser Welding Cobot System.

To answer a common question about laser weld strength and whether laser welding is stronger than TIG, let’s review a case study by IPG.

Laser or TIG Welding: What Would be Your Best Fit?

If you weld sheet metal or thicknesses below 1/4-inch thick, laser welding is usually a better choice than TIG overall.

However, if you weld very thick materials, especially copper, TIG welding is a better option.

TIG equipment requires a lower investment than the cost of the laser welding machine. However, the higher laser welder cost can quickly pay itself off if you do a lot of welding on laser-suitable thicknesses. For better cost comparison, also consider the ease of onboarding new welders and the ability to gain more customers thanks to increased weld quality.

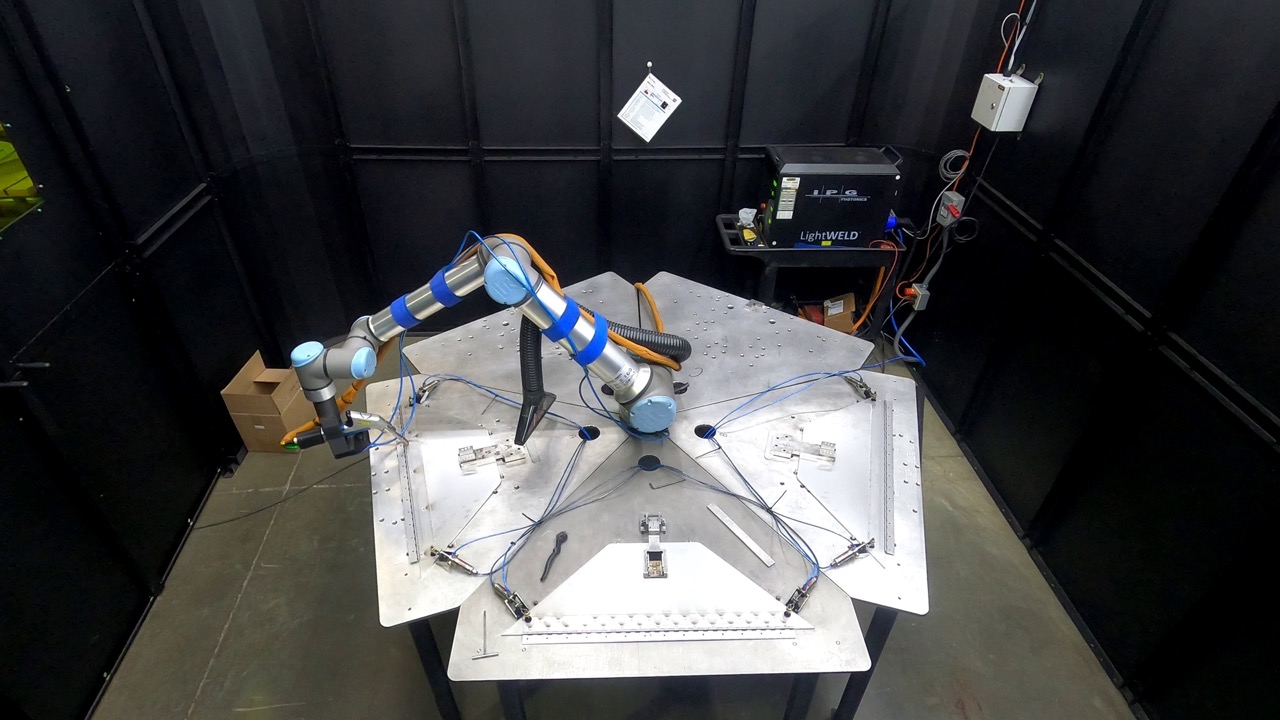

Cobot Systems Laser Welding Cobots Boost Your Production

Manual laser welding is powerful. Automating the process? Significantly more impactful!

While laser welding is powerful, it does require a skilled hand for manual applications. Since you have to move the laser gun extremely fast, it can pose a challenge for manual jobs. Automating the process removes this issue, allowing additional productivity gain and ease of use.

However, traditional welding robots are difficult to use and often require working with programming languages and complex interfaces.

Our industry-first Laser Welding Cobot System doesn’t require any specialized knowledge to operate. You can literally weld parts on the first day. It simplifies the process, allowing you to weld small to medium part volumes with higher productivity, quality, and consistency.

The UR Cap Software offers unparalleled ease of use. Highly intuitive and without any programming, UR Cap Software makes working with the Laser Welding Cobot System a breeze.

Book a no-obligation demo with our team, and we’ll show you just how powerful and simple automated laser welding can be.