Calculating your CNC machine tending cobot ROI requires factoring in fixed and variable costs and understanding how cobots create value in CNC operations.

Tending your CNC machine manually is likely costing you a significant amount of resources. Read on to learn how cobot CNC tending can boost your production and bottom line.

In this article:

• Fixed And Variable Costs Involved In Automating CNC Tasks ›

• How And Where CNC Machine Tending Cobots Create Value ›

• You Can Scale Humans With Cobots ›

• Calculating The Cobot CNC Machine Tending ROI ›

• What’s Stopping Small and Medium-Sized Manufacturers From Using Automation? ›

• Ready To Improve Your Production? ›

Fixed And Variable Costs Involved In Automating CNC Tasks

Before calculating the ROI, let’s first examine the fixed and variable costs for cobot CNC machine tending. You must be aware of both for accurate cost analysis and comparison with manual labor costs.

Fixed Costs

Fixed costs are mostly one-off purchases, such as the hardware and tooling needed to run the cobot operation. Some fixed costs can vary depending on the need for custom fitting for your parts, but overall, these are the costs that’ll stay fixed in your ROI assessment.

Some critical fixed costs you should consider are:

• The cobot itself.

• Mounting mechanism (e.g., for pedestal or ceiling cobot mounting).

• Part presentation system

• End of arm tooling for the cobot to properly handle the parts.

• Regripping/Relocalisation station (if necessary).

• Additional accessories like the door opening system and automated vise, if your CNC • doesn’t have these already.

• Software

Variable Costs

Variable costs are more tricky to assess. These are typically related to labor expenses, opportunity costs, lost productivity, and recurring expenses like software licenses.

You should minimize variable costs as much as possible. With the right cobot system, you can avoid or significantly cut many of the expenses listed below:

• Labor time required to assemble, integrate, and program the system.• Costs for connecting the cobot with the CNC machine. (time and material)

• Ongoing programming costs in labor time. If programming the part requires an hour of your operator’s time, you have to account for that.

• Training time if the software requires your employees to spend a significant amount of time to learn to use the software and system.

• Production downtime during the installation.

• Downtime and loss of profits during programming when switching parts.

• A possible opportunity cost that exists between various systems. For example, choosing a complex system may incur higher labor costs than a less complex system.

The simpler your cobot CNC machine tending system, the lower the ongoing and installation costs will be. Likewise, the less intrusive the installation, the faster and more flexible the cobot-to-CNC connection will be.

For example, the CNC Machine Tending Cobot System can help save resources with:

• All integration types, including the soft integration with your CNC. Unlike many other systems that exclusively require intrusive cobot-to-CNC communications, Cobot Systems can use simple pneumatic actuators mounted on the CNC buttons. The setup is quick and easy, reducing your production downtime. However, a fully wired integration can be more reliable with your CNC. Cobot Systems’ specialists can integrate the cobot in a way that’s most beneficial for your specific operations.

• A highly experienced team. With over 250 CNC machine tending systems installed in the last five years, Cobot Systems’ engineers can have your CNC machine tending cobot running with minimal downtime upon delivery.

• Simplified software. Cobot Systems’ technology for CNC machine tending uses a highly intuitive teach pendant software that your operator can learn quickly, saving you initial and ongoing labor costs when programming the cobot.

• Low to no training. Thanks to simplified software and Cobot Systems’ support, your operators won’t have a steep learning curve, minimizing the time constraints of learning the software.

How And Where CNC Machine Tending Cobots Create Value

Cobot CNC machine tending creates value in several ways, creating ROI over time. Most businesses can see a substantial ROI, depending on your production factors. However, irrespective of specifics, the CNC machine tending cobot will provide value by:

• Increasing your uptime. Cobots don’t take breaks and can work in multiple shifts, allowing you to even achieve lights-out manufacturing if that’s your goal.

• Improving repeatability. A cobot can achieve nearly perfect repeatability, boosting production efficiency and predictability.

• Making the process more robust and stable. If your CNC operator takes sick leave unexpectedly, your shop can experience a drop in production. With a cobot, you’ll get more stability as another operator or someone else from your staff can jump in to keep the cobot running.

• Improving production quality. High cobot accuracy and repeatability can help enhance the quality of the product and reduce scrap.

One particular benefit that’s hard to put a price on is the relief your CNC operators get with cobot tending. This can help you retain your skilled machinists in a tight labor market. With a reduced turnover rate, you’ll benefit more from the acquired staff experience instead of constantly training fresh staff when your operator quits from burnout.

Above all, these benefits and created value combined may give you an advantage over competing businesses that still have their machinists stuck tending CNCs all day.

“Finding people to load and unload the machine was a challenge. The labor we did have was more highly skilled, and we needed to use their talents elsewhere, not have them simply standing in front of the machine all day.”

– Will Fennel, Xcelicut owner.

You Can Scale Humans With Cobots

If you’ve got the right talent, cobots can help them boost their output. Your machinists are probably wasting their time loading/unloading the CNC, and they aren’t even doing it with minimal tolerances in repetition. Of course, they are humans, not robots. So, when placed in a position where they have to do a robot-like task, they aren’t going to shine as much as they could.

Once you give your staff one or more cobots, they can scale the application of their experience/expertise. Imagine if your best machinist had multiple arms, and each of those always performed a task with nearly perfect repetition. That’s what cobots do. They extend your people, helping you do more and better.

Calculating The Cobot CNC Machine Tending ROI

Calculating the cobot CNC machine tending ROI requires setting up goals upfront. These could be increased production throughput and capacity, reduced labor costs, improved product quality, or all of these combined.

You’ll need to factor in fixed and variable costs. Some costs are ongoing, like operational and equipment maintenance costs.

Calculating the exact ROI will depend on your specific production factors. Once you estimate the costs, use the ROI formula below to approximate how long it will take for the cobot to pay itself off.

Payback period = Total Costs / Total Savings per year.

Based on the U.S. Bureau Of Labor Statistics, Computer Numerically Controlled Tool Operators have a mean annual wage of $51,030 and a mean hourly wage of $24.54, with about 187,000 active roles in 2023. Your goal with a cobot should be to improve the profits you make for every paid hour while making your machinists’ jobs less repetitive and cumbersome.

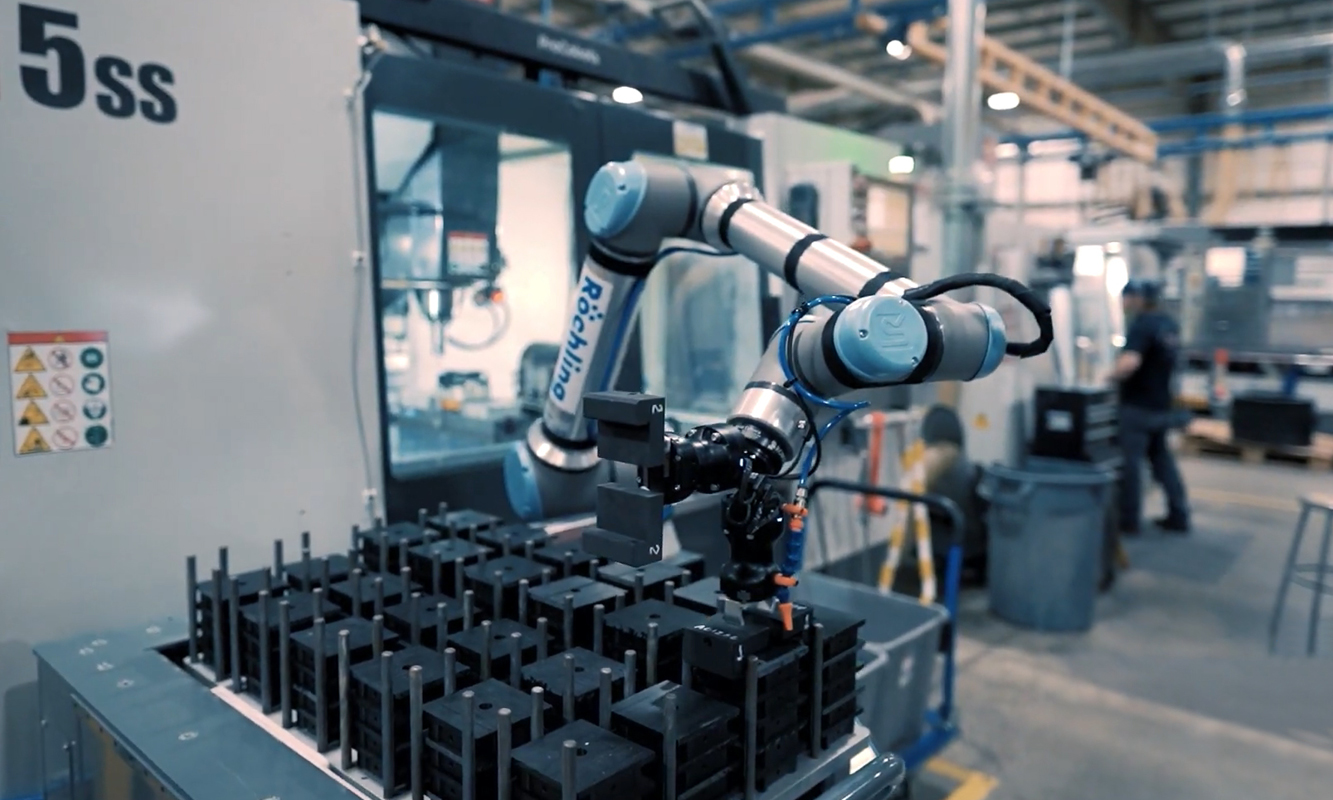

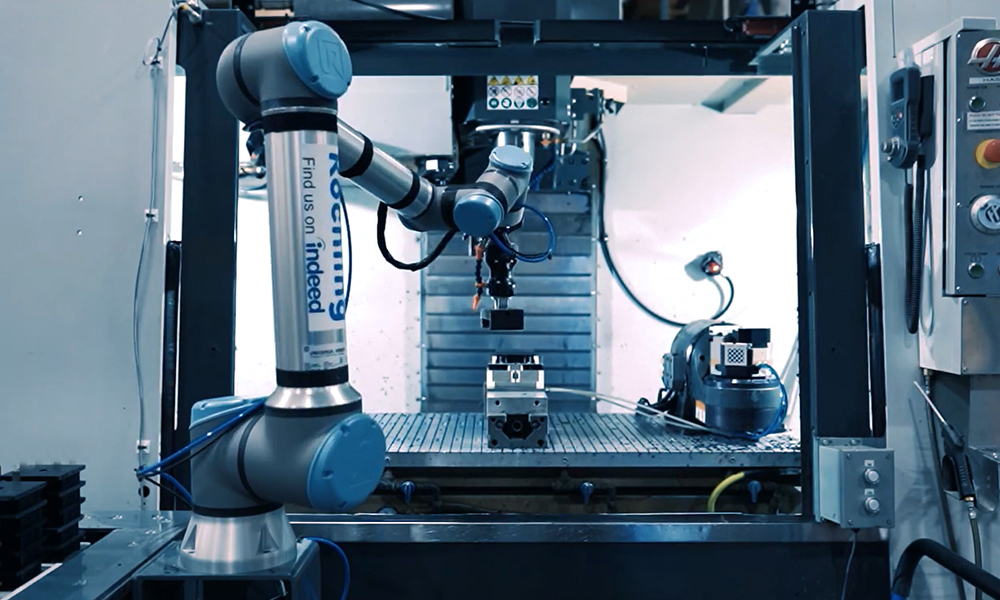

So, if your CNC machine tending cobot system increases the production by 30% (like it did for Röchling Industrial), you can significantly increase the profitability of every shift. Likewise, if you avoid or minimize overtime, you’ll get additional cost savings. Of course, your results can vary. Unlike Rochling Industrial, Xcelicut Precision Machining increased production by 60% on one part family.

So, given the variable nature of calculating the cobot ROI, you should consider the following:

• Total cost of the cobot system.

• Hourly wage for the operator.

• Profits your operator makes per hour (this depends on your parts).

• Estimating the output boost by the operator.

• Using the new earnings by the hour to calculate the ROI.

• Also, consider the cost savings if the cobot can work lights out without an operator until the following day shift.

What’s Stopping Small and Medium-Sized Manufacturers From Using Automation?

Usually, small and medium manufacturers are reluctant to try automation out of fear that the system won’t pay itself off due to its inflexibility for relatively small part batches. Or they worry they’ll need additional staff to run the automated systems.

These are all valid concerns. Automation has traditionally been more suitable for large manufacturers and unattainable for smaller businesses. However, things have changed with the advent of cobots. When using the right cobot system, almost any business can boost its output without hiring more operators or specialized staff.

In the SME 2022 Smart Manufacturing Market Survey, more than 75% of respondents recognized smart technology would increase their company’s competitiveness. However, only 50% indicated a willingness to invest in smart initiatives. So, there’s a significant gap between those who recognize they need help and those willing to act. This gap is your opportunity to take charge and gain an edge others may not have, when using a suitable cobot system for your business.

For example, the Röchling Industrial we mentioned earlier didn’t just increase production by 30%, but the cobot use was easier than they expected. They took the initiative and made their business more reliable and efficient.

“The Cobot system seemed to give us the best advantage to what we needed done. It is very simple to set up, to use, to change over, very quick and efficient.”

– Steve Wilson, Production Coordinator at Röchling Industrial.

Ready To Improve Your Production?

Book a demo with our team, and we’ll discuss how the CNC Machine Tending Cobot System can help with automating your CNC processes. You’ll likely gain an edge you never considered possible and make your CNC operator’s job far less cumbersome.