Is it possible to cut your welding time on a specific part from 90 minutes to 10 minutes?

That’s exactly what Quality Tooling and Repair (QTR) achieved with help from Cobot Systems.

This case study explains how QTR changed their welding processes and boosted productivity with a laser welding cobot from Cobot Systems.

Watch the Case Study Video!

In this case study:

• The Challenge: The 90-Minute Welding Bottleneck ›

• The Search for a Better Way ›

• The Solution: Laser Welding + Cobots ›

• The Result: Cutting Welding Time Down to 10 Minutes ›

• Taking It to the Market: Cobot Systems’ Standardized Solution ›

• Real-World Impact: Benefits Across the Board ›

• A Win-Win Solution ›

• Ready to Change Your Welding Process? ›

• Watch the Case Study Video ›

The Challenge: The 90-Minute Welding Bottleneck

QTR was up against a tough challenge. They were using TIG welding, which is precise, but slow and labor-intensive. It took 90 minutes to weld one part!

This lengthy cycle time was holding them back from hitting production targets and staying competitive.

The Search for a Better Way

Determined to find a faster and more efficient solution, QTR started exploring other welding technologies. They discovered the potential of laser welding, known for its speed and precision with minimal heat distortion.

Intrigued by the possibilities, they decided to see what would happen if they combined this new technology with their existing CNC machine tending experience.

The Solution: Laser Welding + Cobots

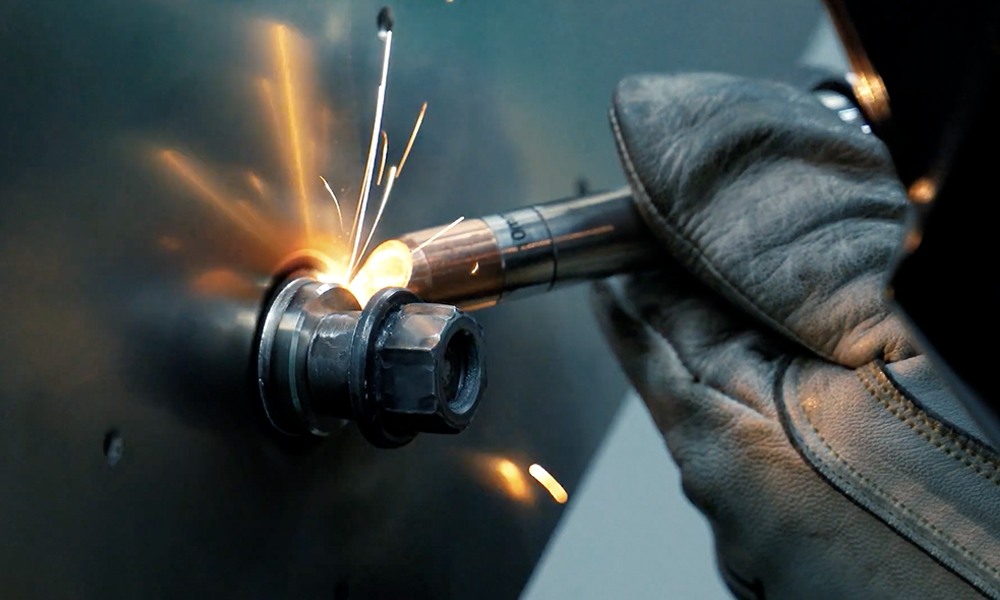

QTR’s lightbulb moment came when they combined a handheld laser welder with a collaborative robot.

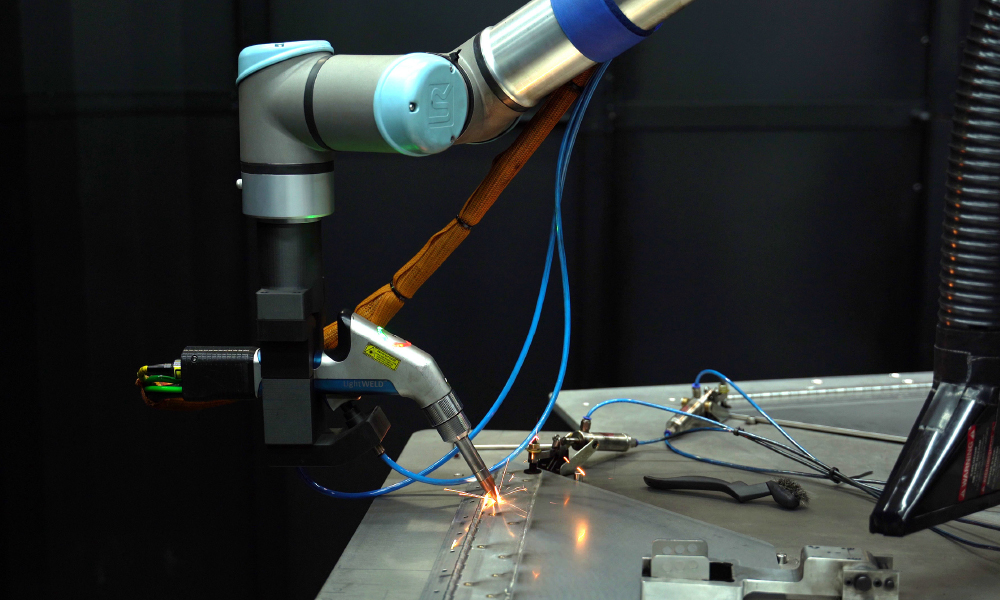

They worked with Cobot Systems to develop an in-house laser welding system that featured a Universal Robots cobot and an IPG handheld laser welder.

Cobot Systems created a special UR Cap software that allowed the UR cobot operator to dynamically set and control the handheld laser welding unit.

The Result: Cutting Welding Time Down to 10 Minutes

With the new cobot laser welding system in place, QTR reduced their welding time from 90 minutes to just 10 minutes per piece. This massive reduction in cycle time boosted their production capacity and improved efficiency across the board.

Taking It to the Market: Cobot Systems’ Standardized Solution

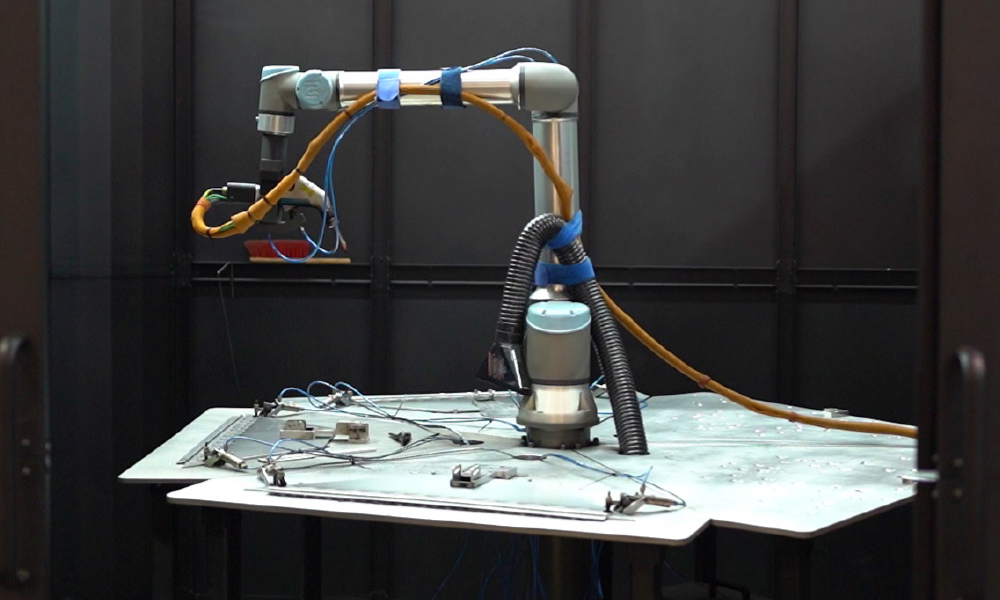

Encouraged by the success of the automated laser welder, QTR and Cobot Systems decided to take their innovation to the market. They developed a standardized laser welding cell that other manufacturers could easily adopt.

Here’s what makes the Laser Welding Cobot System stand out:

• Precision and speed: The system delivers high-quality welds quickly, with much less heat distortion compared to traditional MIG or TIG welding.

• User-friendly: Operators can get up to speed with laser welding in just a few hours, even without prior welding experience.

• Versatility: Ideal for various applications, especially for sheet metal parts up to 3/8-inch thick, making it a game-changer for industries using laser cutting or press brakes.

Real-World Impact: Benefits Across the Board

The cobot laser welding system brought many benefits to QTR and their customers:

• Faster production: They met production targets more efficiently with drastically reduced welding times.

• Better quality: Laser welding provided clean, high-quality welds with minimal distortion, reducing the need for rework.

• Optimized workforce: Skilled workers could focus on more complex tasks while cobots handled the repetitive welding jobs.

• Scalability: The standardized solution from Cobot Systems offered a scalable way for other manufacturers to improve their welding processes.

A Win-Win Solution

QTR’s partnership with Cobot Systems showcases how integrating advanced technologies like cobots and laser welding can solve real-world manufacturing problems.

They didn’t just fix their welding bottleneck—they set a new standard for efficiency and quality in the industry.

Cobot Systems continues to support manufacturers by providing cutting-edge robotic solutions that tackle workforce shortages and improve production efficiency.

The success story of QTR is a shining example of what’s possible when innovation meets collaboration.

Ready to Change Your Welding Process?

Discover how Cobot Systems can make welding faster, cleaner, and more precise for your business. Whether you’re dealing with repetitive tasks or complex welding jobs, our advanced system is designed to meet your needs.

Unlock new levels of productivity and craftsmanship with the Laser Welding Cobot System and IPG Handheld Laser Welder.