Xcelicut Precision Machining faced a familiar challenge that many small machining shops encounter: finding laborers to do the monotonous job of loading and unloading CNC machines.

With a small team of five, including owner Will Fennell, Xcelicut needed a solution that would allow them to use their skilled laborers elsewhere and improve productivity.

This article explores how Cobot Systems’ CNC Machine Tending Cobot transformed Xcelicut’s operations, increasing output and freeing skilled labor for more important tasks.

The Challenge

Operating for just over three years, Xcelicut specializes in production turning with a tight-knit team. According to Fenell:

“Finding people to load and unload the machine was a challenge. The labor we did have was more highly skilled, and we needed to use their talents elsewhere, not have them simply standing in front of the machine all day.”

Xcelicut required a solution to automate repetitive tasks like machine tending, especially for the evening shifts. They needed a system that was easy to learn, program, and operate with minimal supervision, ensuring safety and flexibility.

The Search for a Solution

Fennell began exploring automation options and was particularly interested in a solution that could run unattended for a few hours in the evenings. After reviewing various options, he approached Brian at Cobot Systems.

Fennell recounts: “Seeing the ease of use and the flexibility around the Cobot System made me want to talk to them more. I had a specific family of parts that I was planning to automate, so I went to Brian at Cobot Systems and told him what we were working on.”

The collaborative approach with Cobot Systems involved selecting the right robot size and designing the tray and table setup to meet Xcelicut’s needs.

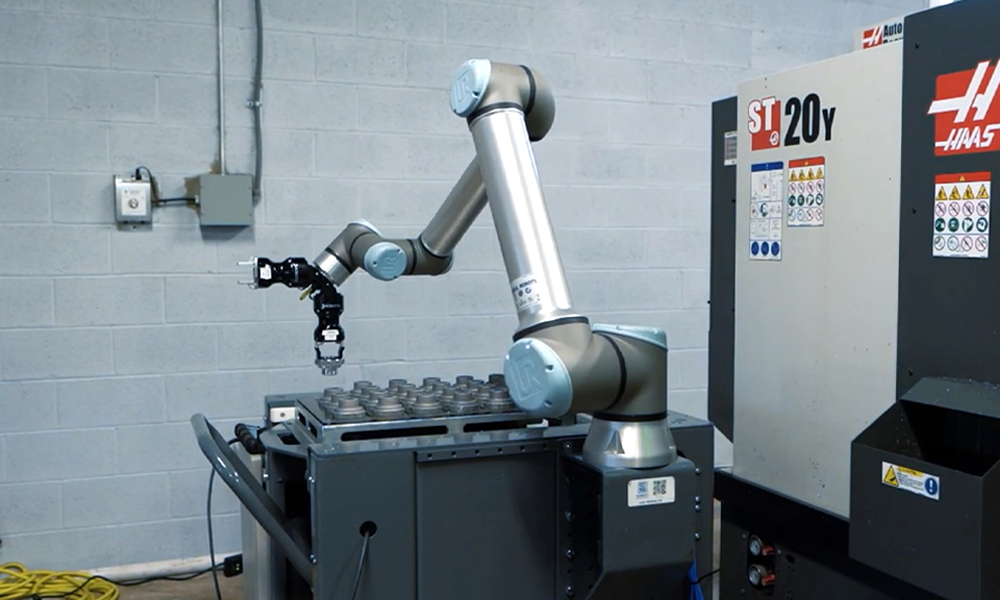

The Solution: CNC Machine Tending Cobot System

Cobot Systems provided a customized CNC Machine Tending Cobot. This system was designed to integrate seamlessly with Xcelicut’s existing machinery.

The integration process was remarkably swift:

“They brought it in and integrated it in probably less than an hour. We started training on it, and we had parts running that day.”

Implementation and Training

Xcelicut had no prior experience with robots. However, with on-site support from Cobot Systems, Fennell’s team quickly adapted:

“My team member, who’s currently programming and working with the robot, was able to pick it up extremely quickly. The Cobot Systems team helped him work through the best way to handle the parts and move the robot.”

The straightforward training process allowed Xcelicut to move from novice to proficient operation in a short time, showcasing the user-friendly nature of the Cobot System.

Results

The impact of implementing the CNC Machine Tending Cobot was significant:

1. Increased output: Production jumped from 100 parts per day to 160 parts per day for a particular part family, even before factoring in additional unattended operation time.

2. Labor optimization: Skilled workers were freed from monotonous tasks to focus on more complex and fulfilling work. Fennell noted: “For them to just be able to load the Cobot System with raw material, hit the button, come back and inspect one every once in a while, and then have the tray of parts be complete – they were ecstatic.”

3. Operational efficiency: The Cobot’s ability to press machine buttons as an operator would, without additional integration complexity, simplified the transition to automation.

The Takeaway

Xcelicut’s experience demonstrates how small machining shops can significantly benefit from automation with minimal disruption. The CNC Machine Tending Cobot from Cobot Systems provided a reliable solution that improved productivity and optimized labor use.

Fennell’s advice:

“Don’t be afraid to bring the robot in. It’s going to open up a world of possibilities that you didn’t think of before. Even other products you’re currently manufacturing – you’ll see them in a different way and you’ll want to put everything on the robot.”

Transform Your CNC Operations Today

Ready to boost your production and free up skilled labor? Discover the benefits of automation with Cobot Systems’ CNC Machine Tending Cobot. Contact us today to learn more and start your automation journey today!

Cobot Systems specializes in collaborative robot solutions that simplify CNC machine tending processes. With a focus on ease of use and integration, Cobot Systems offers scalable automation tailored to your manufacturing needs. Visit Cobot Systems for more information.